ˇ@

Pneumatic & Hydraulic control practice

ˇ@

CHAPTER 1 TRADITIONAL PNEUMATIC CONTROL

ˇ@

1-1 Preface

ˇ@

Traditional Pneumatic control uses general

Pneumatic control components to control the pressure, Direction, and

Flow rate of the compressed Pnenumatic provided by the Pnenumatic

Compressor , and then adjusts the

pressure after accumulating, timing, counting or processing to vacuum with

auxiliary components The compressed Pnenumatic is sent to pneumatic cylinders,

pneumatic motors, pneumatic rotary cylinders, or vacuum suction cups and other

pneumatic action components, which are used as the output of the system to

provide power for processing machines or industrial automation systems.

ˇ@

1-1.1 pressure control valve (Pressure

control valve)

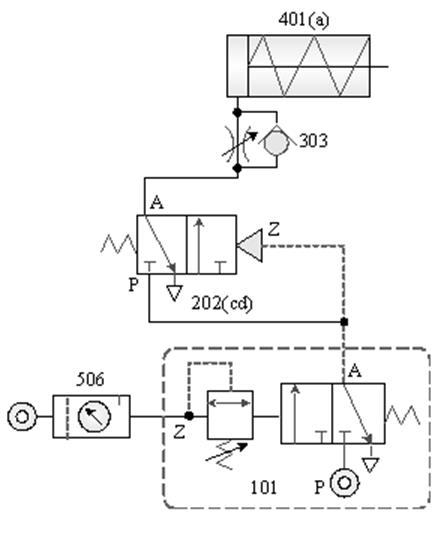

101 sequence valve : it is a Normally Closed(NC) valve, and when it is

not in motion, there valve is closed ; when the inlet pressure is greater than

the setting value of the adjustment spring, the valve opens.

ˇ@

ˇ@

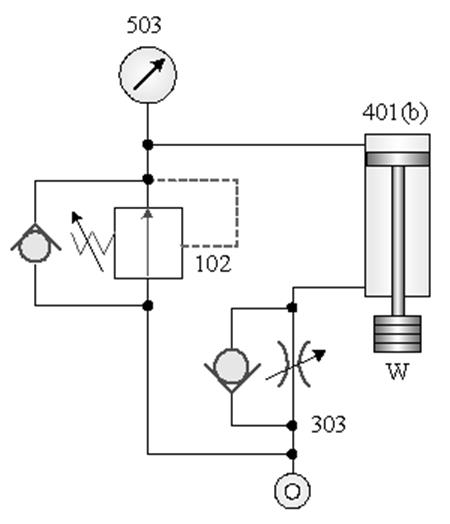

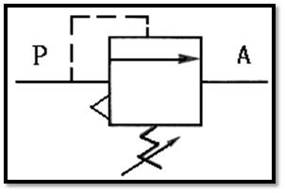

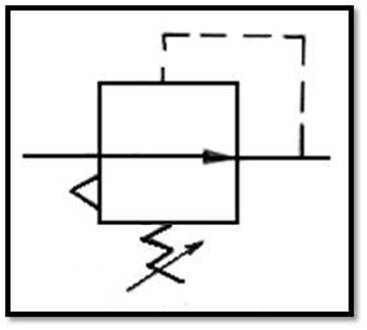

102 Pressure reducing valve : It is a Normally Open(NO) valve. When it is not

actuated, the valve is opens . The pressure

drop of the outlet secondary pressure can be set by adjust the pressure

adjusting spring.

ˇ@

ˇ@

ˇ@

103 Drain valve : It is a Normally Closed (NC) valve. When it is not operating, It is

closed ; when the inlet pressure is greater than the setting value of the

adjusting spring, the valve opens and the pressure is released. It is often used

for the safety pressure setting of the system.

http://www.aliexpress.com/popular/manual-relief-valve.html

104 pressure switch: It is a pneumatic-electric conversion element. When it is not activated,

the circuit c-b on and c-a off ;

when the inlet pressure is higher than the setting value of the adjustment

spring, the circuit switches to c-a on and c-b off.

ˇ@

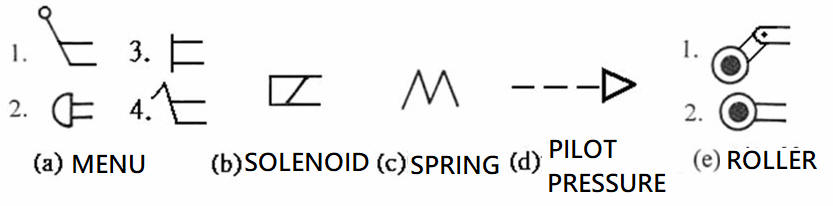

1-1.2

Direction control valve (

Direction control valve)

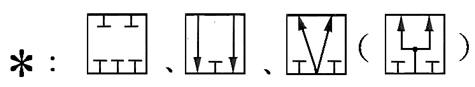

Operation method:

ˇ@

ˇ@

ˇ@

ˇ@

ˇ@

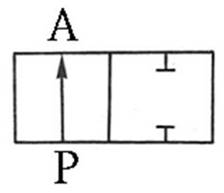

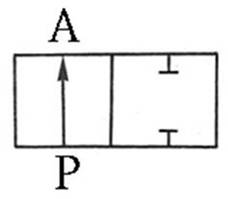

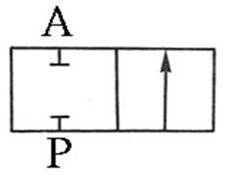

201 Two-port two-position (2/2) Directional valve:

It has two forms : Normally

Open (NO) and Normally Closed (NC) . It is often used to control the opening or

closing of the Pnenumatic pipe.

ˇ@

ˇ@

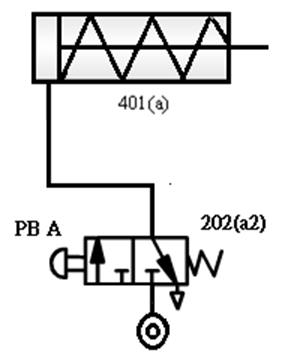

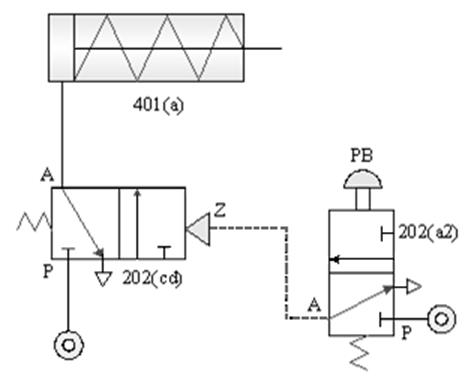

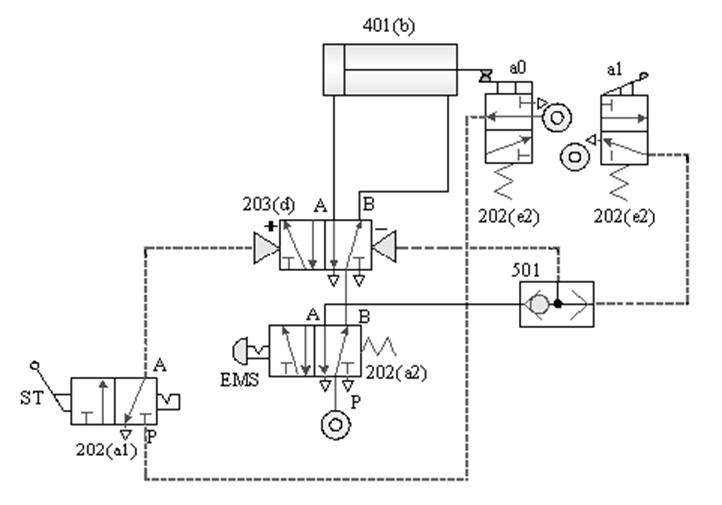

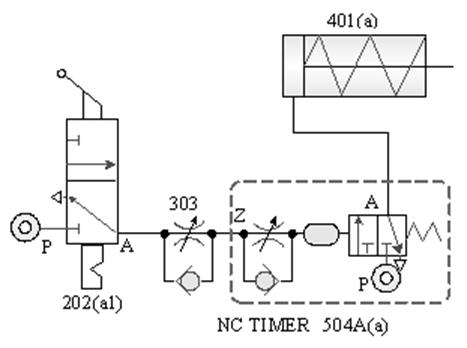

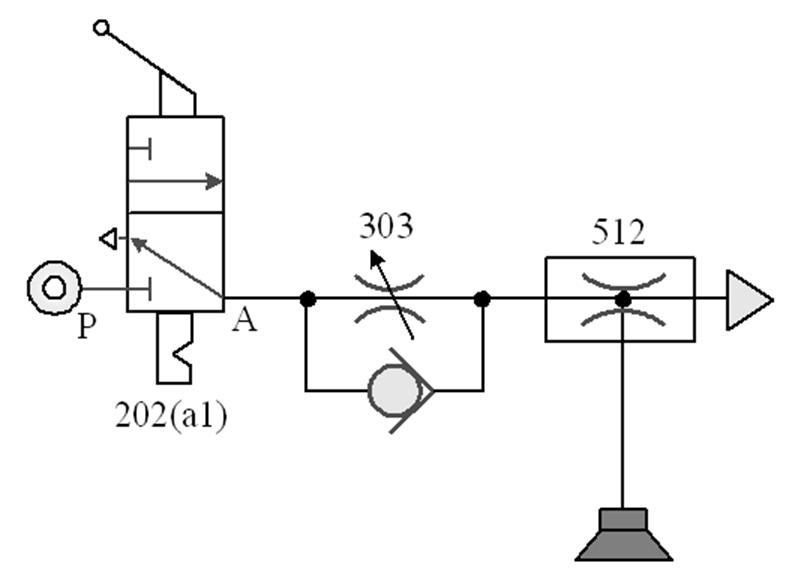

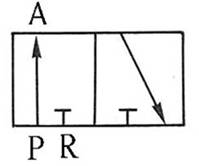

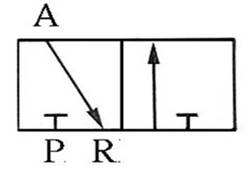

202 Three-port two-position (3/2) Directional valve:

It has two types of Normally

Open(NO) (NO) and Normally Closed(NC) (NC) . It is often used to control single-acting cylinders

or single-acting pneumatic motors. It can also be used to control the opening

or decompression of pneumatic lines.

ˇ@

ˇ@

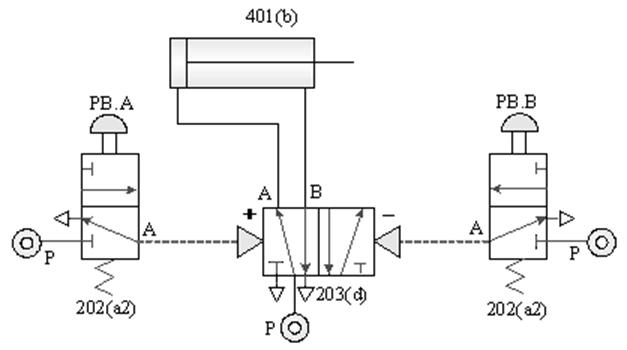

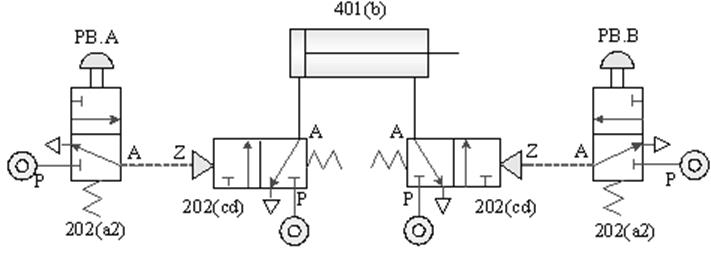

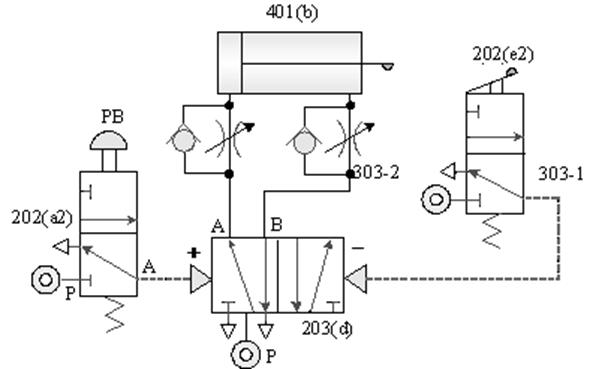

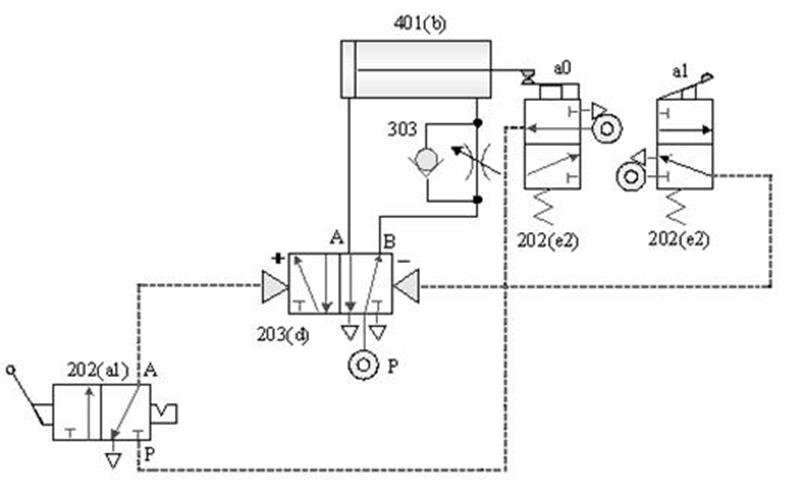

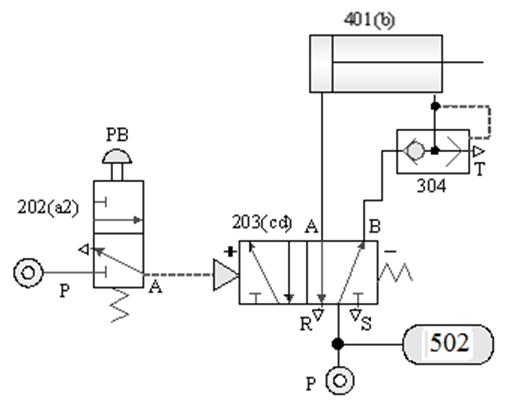

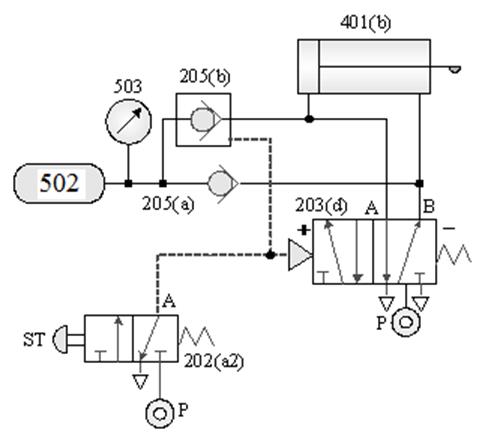

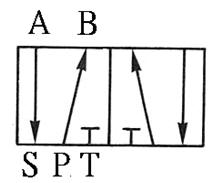

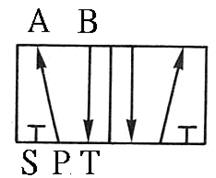

203 five-port two-position (5/5) Directional valve:

a Directional control element, often used for the

control of double-acting pneumatic cylinders or double-acting pneumatic motors.

It can also be used for cascade design of the return valve for the purpose of

changing the stage. The difference between right-hand drive and left-hand drive

is similar between European and American regulations. There are also

differences between left position Pˇ÷B pass, right position Pˇ÷A pass, left position Pˇ÷A pass, and right position Pˇ÷B pass.

ˇ@

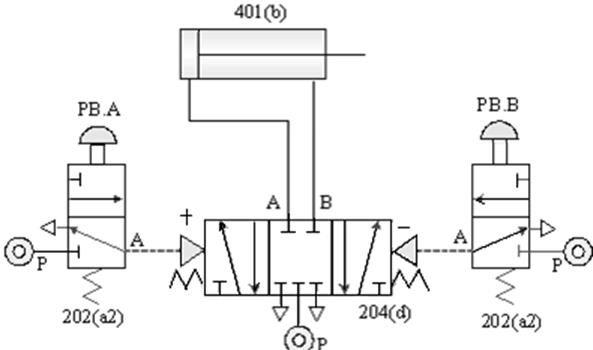

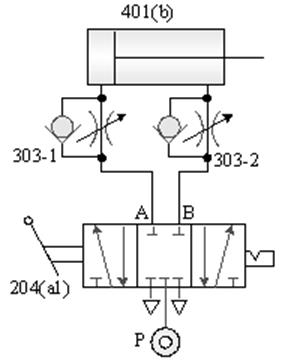

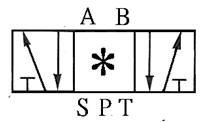

204 five-port three-position Directional valve:

Directional control element, often used for the control

of double-acting pneumatic cylinders or double-acting pneumatic motors;

depending on the control requirements, it has a neutral shut-off lock, a

neutral exhaust pressure and a neutral position Different forms such as

bilateral Pnenumatic intake.

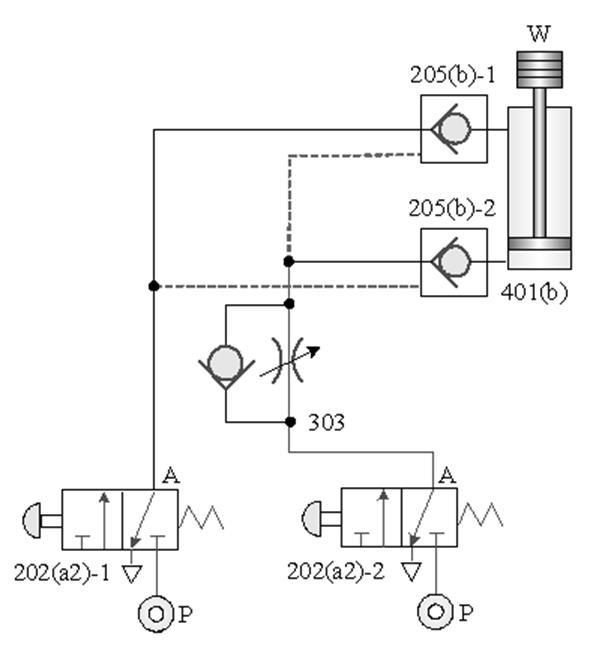

205 check valve: also known as check valve. It is a one-way valve with a forward path and

no reverse Direction. It is often used to prevent back Flow, pressure lock, or

use with a control valve to establish a bypass path ; if there is an

occasional reverse For access requirements, a pilot check valve can be used to

open it with pilot pressure.

ˇ@

ˇ@

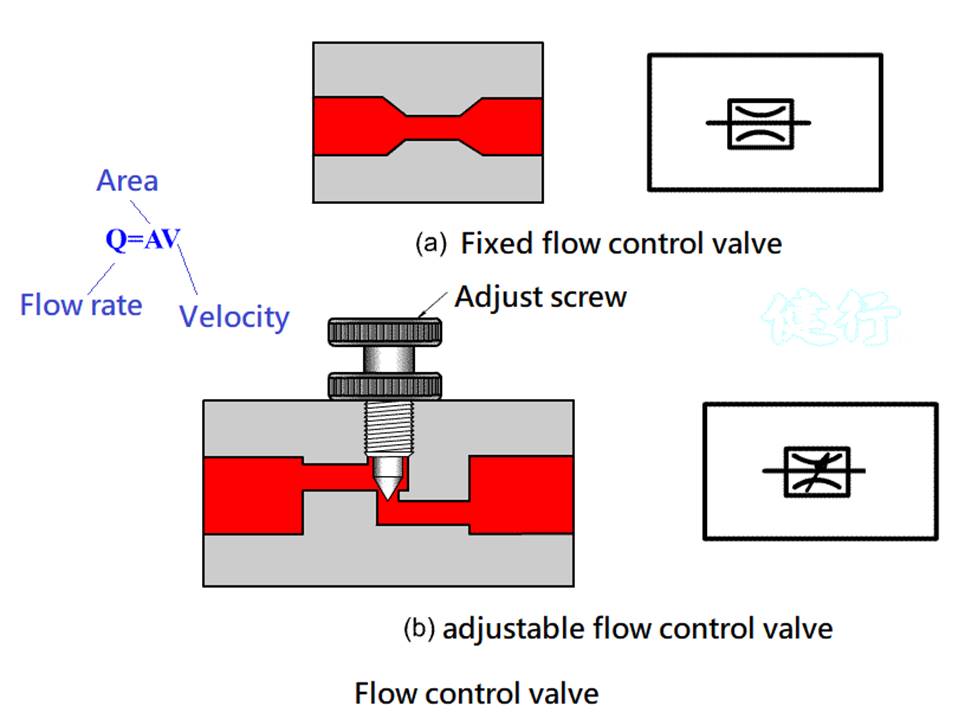

1-1.3

Flow control valve

301 Throttle Valve: Reduce the Flow channel area and adjust the

Pnenumatic Flow to achieve the purpose of adjusting the actuator speed.

ˇ@

302 STOP valve: also known as on-off valve, which controls the opening and closing of

the Flow channel.

ˇ@

http://www.hj-hg.com.tw/product-detail-208439.html

ˇ@

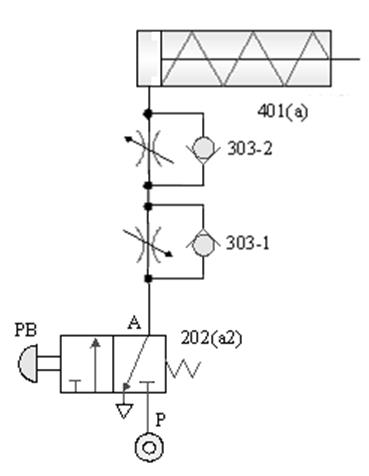

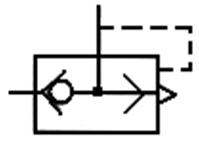

303 comes with a check throttle valve: also known as a Flow regulator (FR) , for one-way speed regulation.

ˇ@

ˇ@

304 Quick exhaust valve: Pneumatic P enters A out, A enters R out ( exhaust ) ; A port is installed at the exhaust port of the actuator to provide a quick

exhaust path to increase the speed of the actuator.

ˇ@

ˇ@

ˇ@

ˇ@

ˇ@

1-1.4 pneumatic actuator

ˇ@

401 Pnenumatic Cylinder: The piston is driven by Pneumatic, which converts

Pneumatic energy into pushing and pulling mechanical energy components.

ˇ@

ˇ@

ˇ@

ˇ@

ˇ@

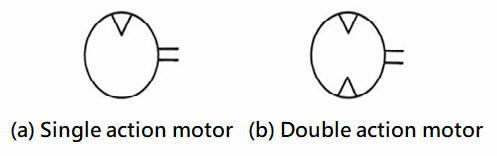

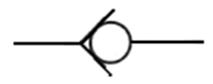

402

Pneumatic Motor: A component that converts Pneumatic energy into

continuous rotating mechanical energy.

ˇ@

ˇ@

403 rotary cylinder: also known as a rotary cylinder , a

component that converts Pneumatic energy into a fixed-angle rotating

mechanical energy.

ˇ@

http://www.68jd.com/biz/2009522/55587.html

ˇ@

1-1.5 auxiliary element

ˇ@

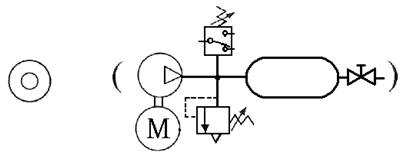

501 Pneumatic

Source : Provides

compressed Pnenumatic as the driving force for the operation of the Pneumatic

system.

ˇ@

ˇ@

ˇ@

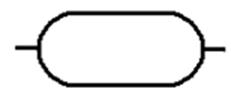

502

Pnenumatic Recervoir / Accumulator : Multi-Pnenumatic reservoir for storing compressed Pnenumatic conveyed

to the compressor; used for Stabilize,

supplement Flow and act as a temporary pressure source.

ˇ@

ˇ@

ˇ@

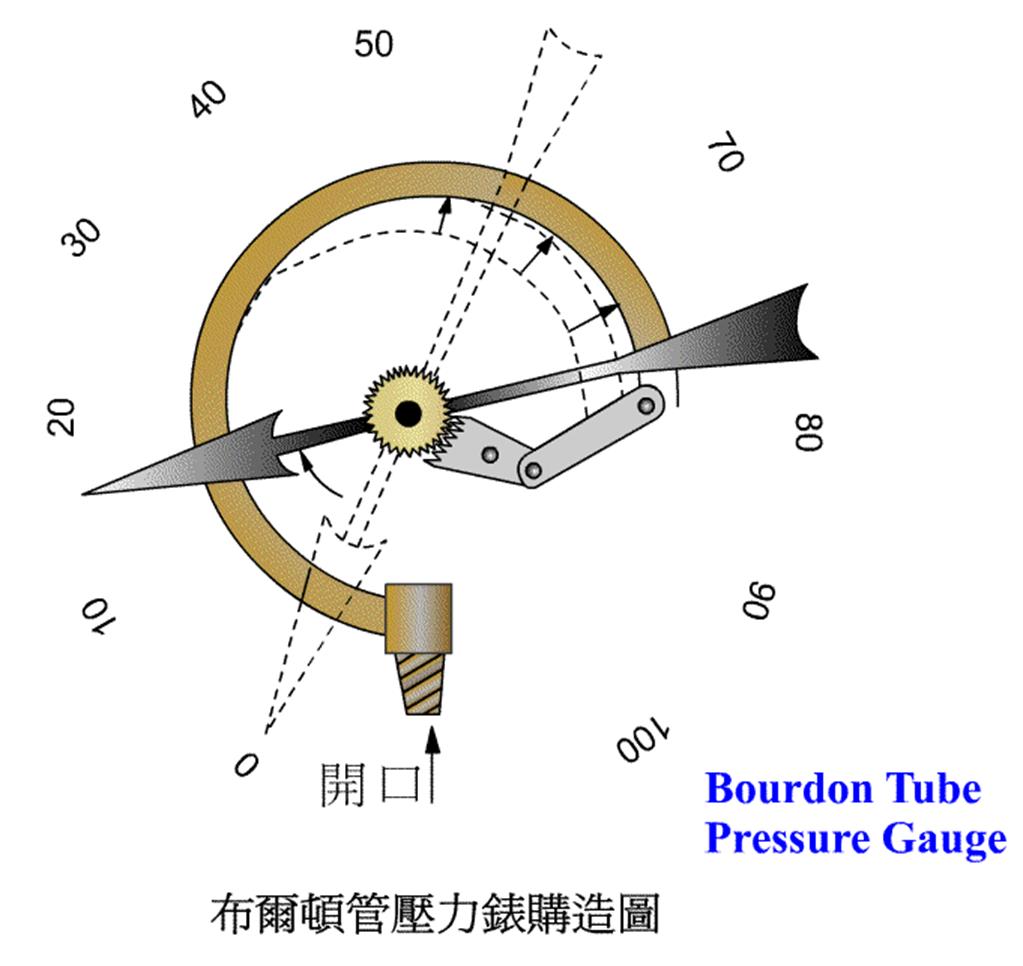

503 Pressure Gauge : Based on the principle of Bourdon tube , it displays the pressure value in the system.

ˇ@

ˇ@

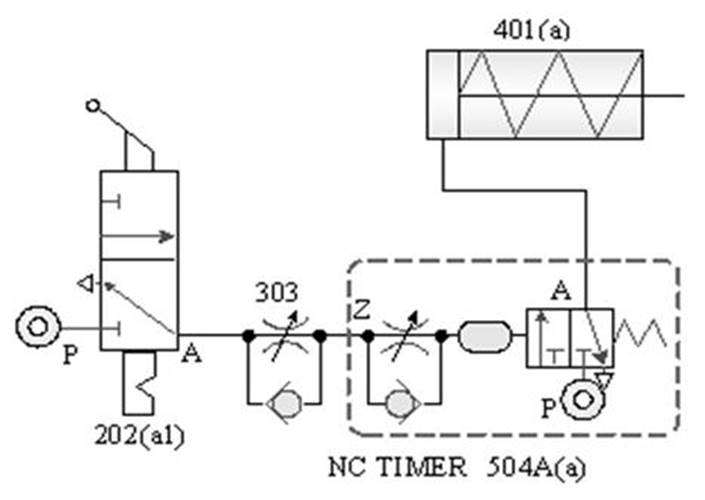

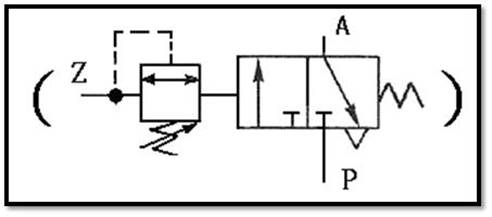

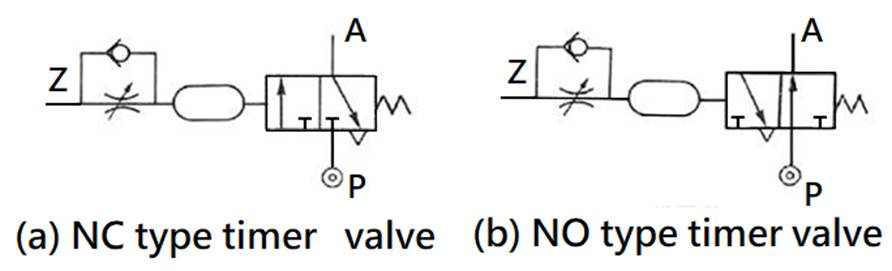

504 Timing valve (TIMER): , the guiding pressure uses the principle of throttling

and Pnenumatic chamber charging to achieve the purpose of timing actuation. It

has two control modes: timing actuation and timing reset, There are two types

of actions, as well as Normally Closed(NC) and normally Open(NO).

timing actuation timing valve

.

ˇ@

Timing reset NO timing

valve

CNS SYMBOL

ˇ@

ˇ@

ˇ@

505 Pneumatic Pipe : The pipe fittings is for conveying Pneumatic, beside the difference in material and size, are

divided into hard pipe and hose.

ˇ@

ˇ@

506 three-piece combination (FRL combination): Pnenumatic conditioning components, including Filter, pressure Regulator, and Lubricator

in sequence, also known as three-point combination.

ˇ@

ˇ@

ˇ@

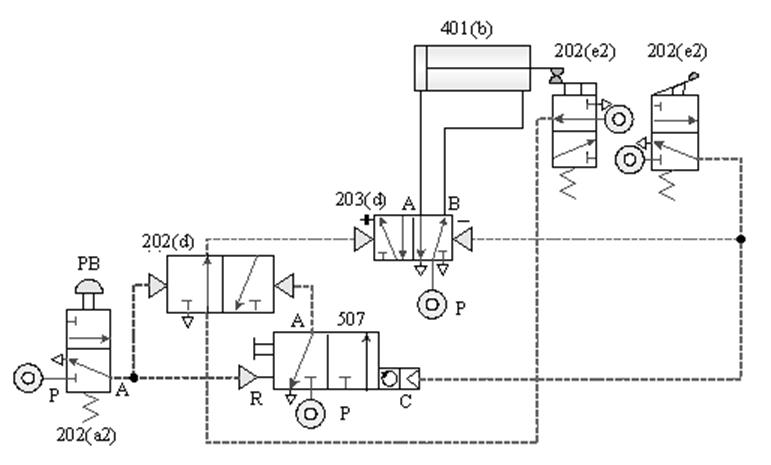

507 Counting valve (Counter) : Uses the on / off of the input pilot Pneumatic to

count the times. When the on / off times reach the set value, the valve witches; where P is the pressure Pnenumatic inlet, A is the Pneumatic outlet, and C (Z ) Is the counting terminal, R (Y) is the Pneumatic zero return (RESET)

terminal, and RST is

the manual zero return.

ˇ@

Decrement (-) type counter

Increment (+) type counter

508 pressure

increaser: apply pressure to the big piston to push the small

piston, and use the characteristic that the pressure is inversely proportional

to the piston area to achieve the purpose of boosting.

ˇ@

ˇ@

ˇ@

ˇ@

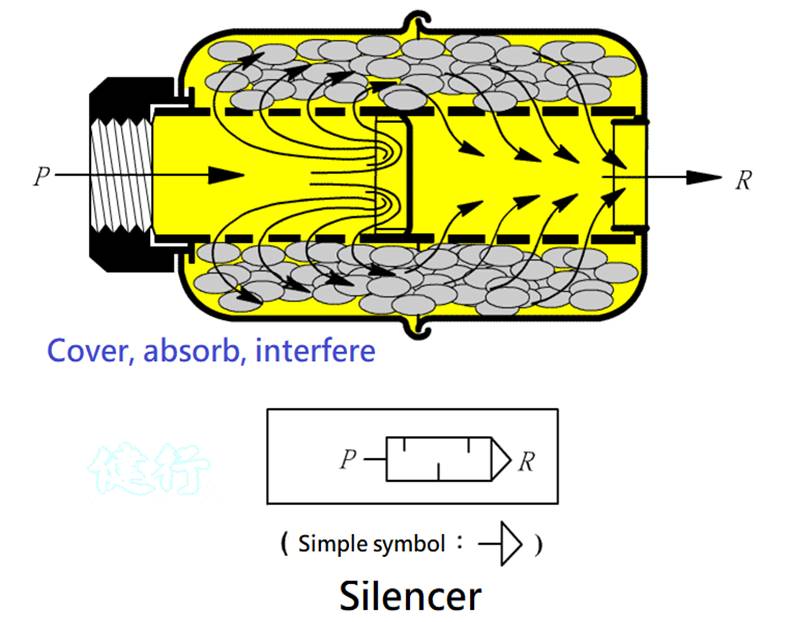

509 silencer : installed at the exhaust port of the pneumatic component, to achieve

the purpose of silence by cover,absorption and interference.

ˇ@

SHAKO

https://www.shako.com.tw/webls-zh-tw/accessories/09.htm

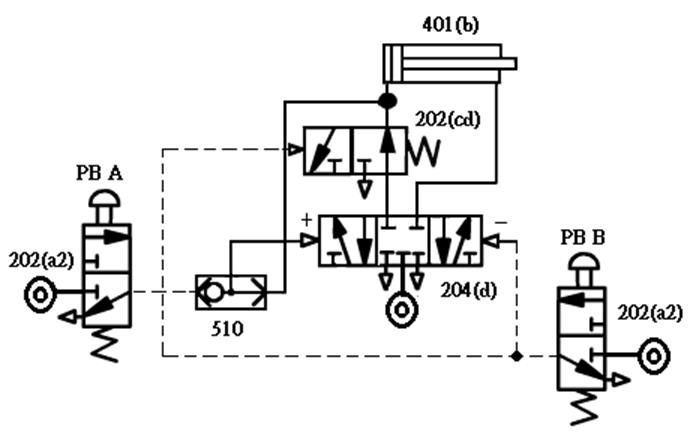

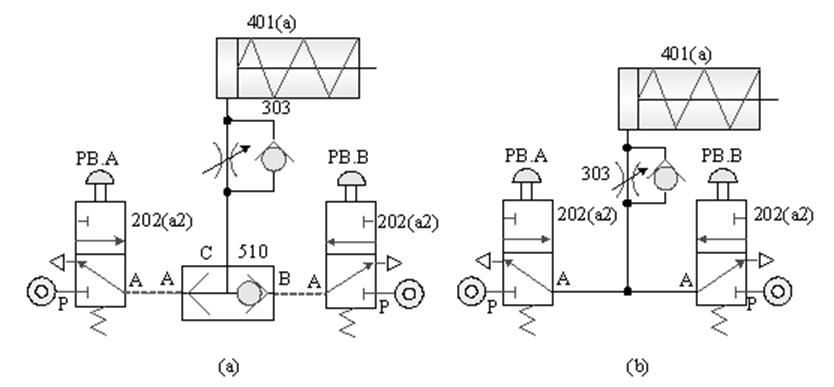

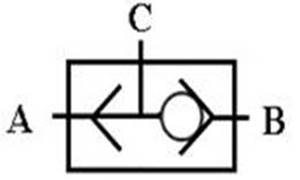

510 shuttle valve : logical OR , C = A+B ; when there is pressure input at either end of A and B , there is pressure output at end C.

ˇ@

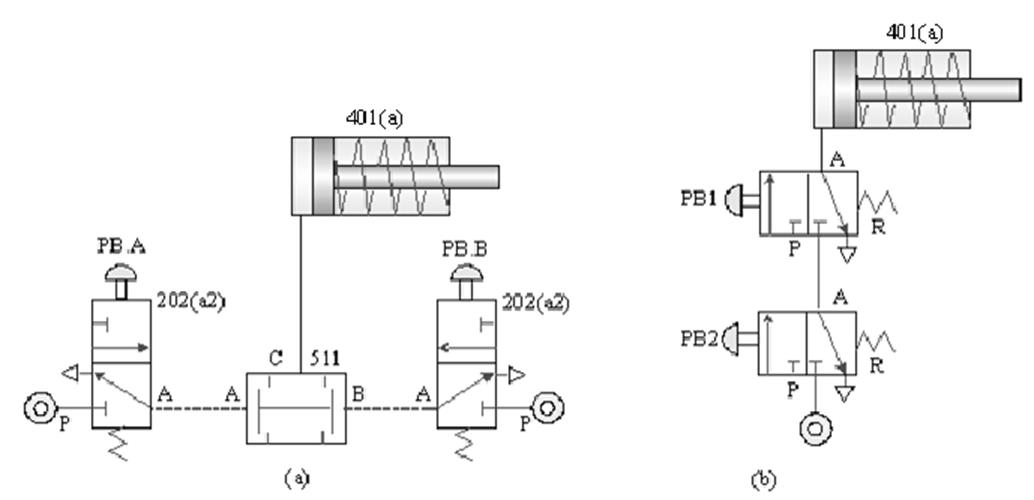

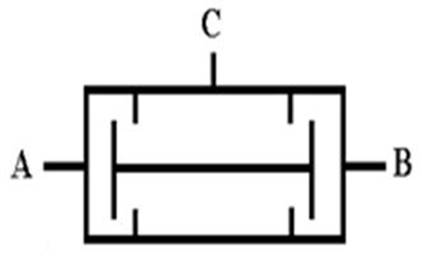

51 1 Double-pressure valve : logical AND , C = AˇŃB ; when both ends A and B have pressure input, there is pressure

output at end C.

ˇ@

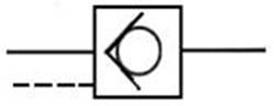

512 vacuum generator : It is driven by compressed Pnenumatic using

the principle of venturi. When the Pneumatic Flows through the nozzle, the Flow

rate increases, and suction is generated at the opening due to the pressure

difference. Generally, it can generate a vacuum pressure of about

tens of KPa

( a few tenths of a bar) .

ˇ@

ˇ@

ˇ@

ˇ@

ˇ@

1-2 Precautions

1. The operation should be preceded by all the Flow control valve to the

minimum; delay valve, the valve zero count; and check whether there is water

inside the bowl FRL, if the bolts loosen the drain cup bottom, and the

pressure is adjusted 3~8KGf/cm 2 .

2. When connecting the

circuit, the pressure source should be closed to prevent a large amount of Pnenumatic leakage

or the pipeline swinging and hurting people.

3. When assembling and disassembling the pneumatic tube, press

down the quick-disconnect joint before pulling it out . In case of a new pipe or joint with a tight bite, it is not easy

to pull out the quick release joint by pressing down. Push the Pnenumatic tube

forward to disengage the inverted teeth before pulling out the Pnenumatic tube.

Do not pull hard to avoid damage to the Pnenumatic tube wall and joints. .

4. After connecting the circuit, check whether all the connectors are

properly connected before turning on the Pneumatic source to prevent the

pipeline from tripping when the pressure is connected.

5. The unused components and Pneumatic tubes on the machine should be

placed properly and do not fall to the ground.

6. Do not blow Pneumatic to others, so as to avoid injury caused by Pneumatic

or impurities in the pneumatic.

7. The

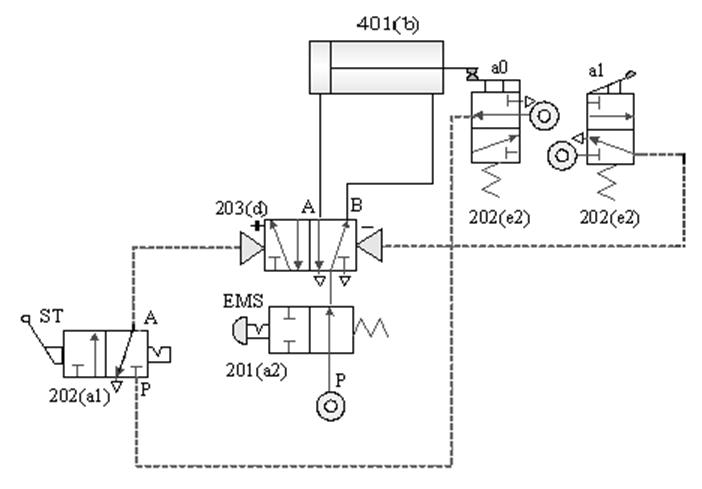

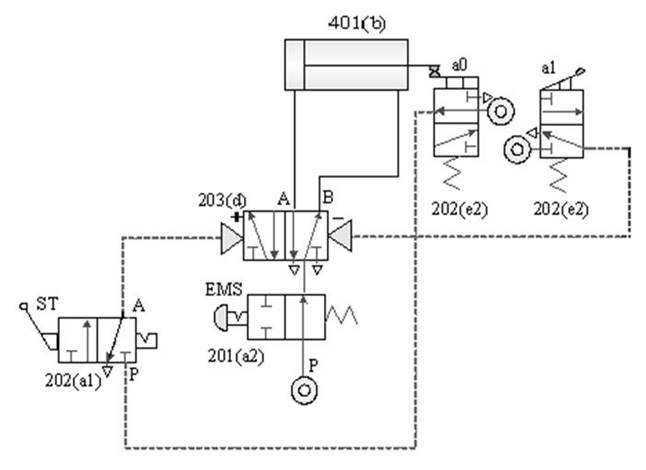

solid and dashed lines in the circuit are pneumatic pipelines. Generally

speaking, the solid line is the operating pressure, and the dashed line is the

pilot pressure. When the two lines intersect and are not connected, no

cross-line processing is performed. If they are connected, the intersection is

indicated by a dot.

8. When assembling the control valve, confirm the

inlet and outlet positions of each valve , and mark the piping according

to the Direction of the arrow or the pressure input end ( P) , output end ( A , B) , pilot pressure ( X , Y), etc., so as to avoid incorrect connection.

It has a function; if the control valve leaks a lot when the pressure is turned

on, it is mostly caused by the reverse connection of the inlet and outlet

pipelines.

9. When assembling the actuator, confirm the extension Direction of the

pneumatic cylinder, the inlet and outlet of the pneumatic motor or the rotary

cylinder, the normal pressure output port of the Directional control valve and

the installation position of the roller valve (the double roller valve is installed on the stroke of the pneumatic cylinder

At the end, the installation position of the single roller valve must be moved

to the inside ) and the contact Direction of

the roller valve (the roller is on the outside ) .

10. The assembly way throttle valve when the bypass check confirmation

opening Direction, the speed control loop does understand the way the intake throttle ( metered into, Meter in) or an

exhaust throttle ( measured out, Meter OUT) .

11. If

there is any abnormal movement or situation, immediately press the emergency

s (EMS) button or turn off the Pneumatic source, and then turn it on again after

removing the abnormal situation.

12. After the circuit is connected, the pressure should be started after

confirming that there are no obstacles on the pneumatic cylinder stroke; do not

s or place objects in the pneumatic cylinder stroke to avoid danger or damage

during operation.

13. After starting the circuit, you should follow the operating steps

and record the operation status one by one. If the system does not operate at

all or does not operate correctly, you can turn off the pressure and check the

Pneumatic circuit and the aforementioned precautions to find out the errors and

eliminate the obstacles. After removing the obstacle, restart the pressure

start circuit again.

14. After all internships are completed, the Pneumatic source should be turned off, the

pipelines and components should

be collected,

the work surface should

be cleaned,

and the use record form should

be filled

in.

ˇ@

ˇ@

1-3-1ˇ@basic

application --- three-point combination basic

adjustment exercise

Practice purpose: to understand the

characteristics of three-point combined filtration, pressure regulation

and lubrication .

1-3-2 Direction control --- Single-acting cylinder control circuit

Practice purpose: to understand the motion control

of a single-acting cylinder.

A.

Direct control

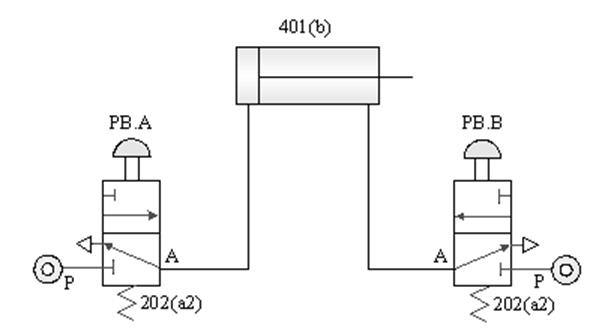

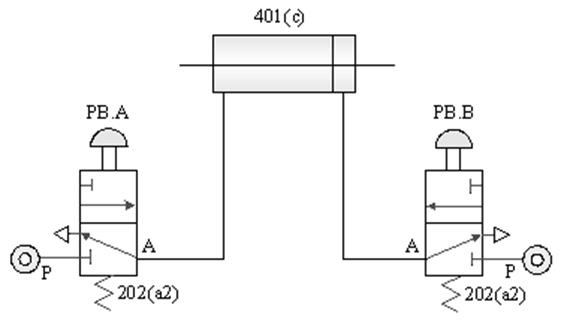

1-3-3 Direction control --- Double-acting cylinder control circuit

Practice purpose: to understand how to switch

the Direction of a double-acting pneumatic cylinder with a button valve.

A. Single rod cylinder manual Direct

operation circuit

B. Double rod cylinder manual Direct

operation circuit

C. Double-acting cylinder pulse pilot pressure in

Direct control loop

1-3-4 Directional Control ---5/3 Directional Valve Control Circuit

Practice purpose: to understand the role of

pilot pressure and the Direction switching of the pneumatic cylinder by the five-port

three-position valve.

A. 5/3

Directional valve stationary waveguide pressure control loop

B. 5/3 Directional valve pulse pressure control circuit ( Pneumatic self-protection )

C. 3/2

Directional valve stationary waveguide pressure in

Direct control loop

1-3-5 Direction control --- Double-acting cylinder EMS emergency s control loop

Practice purpose: to understand the application

of pneumatic cylinder emergency s control.

A.

After pressing the emergency s, continue to operate

the circuit after the emergency s is released

B. Emergency return to the loop after

pressing

C. The return control

loop after the emergency s is released after pressing

1-3-6 Flow control --- measuring in and out speed control loop

Internship purpose: to understand the principle

of speed control with check throttle valve.

A. Single-acting

cylinder manual control

B. Double-acting

cylinder speed control circuit

C. Double-acting cylinder reciprocating speed

control circuit

D. Double-acting cylinder automatic reciprocating

speed control circuit

1-3-7 Flow control --- quick exhaust valve action circuit

Internship purpose: to understand the operating

principle of rapid exhaust valve speed increase.

1-3-8ˇ@Pressure

control --- sequence valve actuation

control loop

Internship purpose: to understand the operating

characteristics of sequence valves.

1-3-9 Timing control --- timing action and delay reset control loop

Practice purpose: to understand the application

of timing action timing valve in delayed return.

1-3-10 Timing control --- Double acting cylinder timing action circuit

Internship purpose: to understand the operating

principle of the delay valve.

2. Use equipment and circuits:

ˇ@

1-3-11 Counting control --- double-acting cylinder counting circuit

Practice purpose: to understand the control of

pneumatic cylinder counting.

1-3-12 Series and parallel

control ---AND circuit

Practice purpose: to understand the operating

characteristics of series and parallel circuits.

A. Series control ---AND circuit

B. Parallel control ---OR loop

1-3-13 Load control --- load cylinder locking circuit

Practice purpose: to understand how to use the

pilot check valve to lock the load cylinder.

1-3-14 Load control --- load cylinder balance circuit

Internship purpose: to understand how to balance

the load cylinder with a bilateral pressure-reducing valve.

1-3-15 Negative pressure

control --- vacuum generator application

circuit

Internship purpose: to understand the operating characteristics

of the vacuum generator.

1-3-16

Pressure

Accumulation Control --- Double-acting Cylinder Impact

Circuit (It is recommended to use

a pressure pipe of 6 mm or more for this

circuit )ˇ@

Practice purpose: to understand how to charge a

pressure accumulator to make a pneumatic cylinder produce an impact action.

ˇ@

1-4 Application

circuit

ˇ@

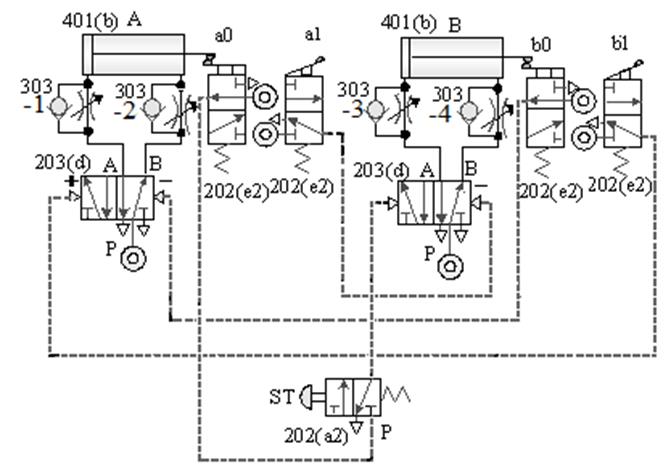

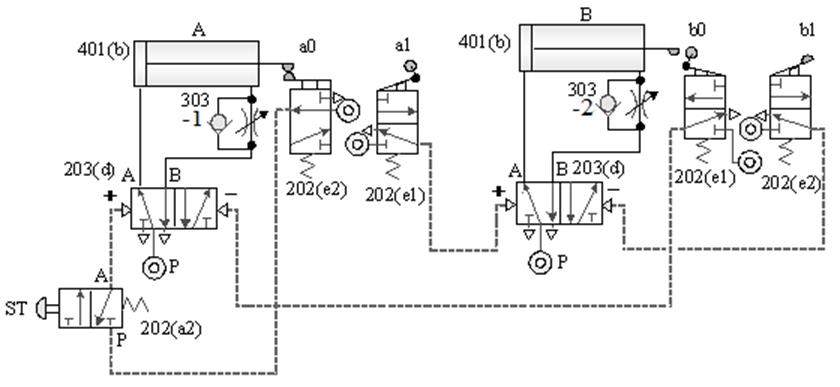

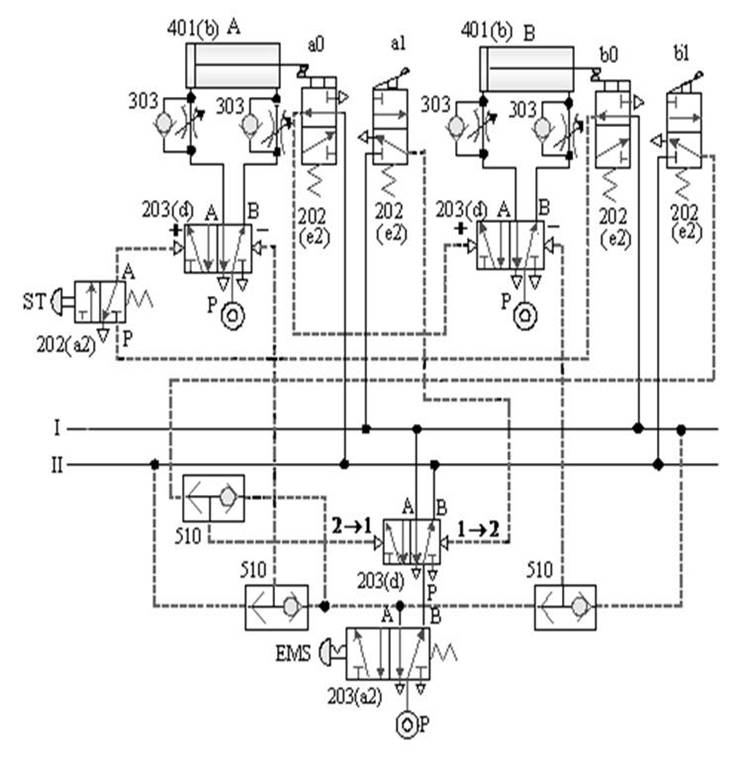

1-4-1 Sequential control --- Double cylinder sequential action circuit

Practice purpose: Two pneumatic cylinders

cooperate with roller valve and pilot valve for sequential action.

A. Double cylinder sequential action circuit

B. Double cylinder sequence action circuit

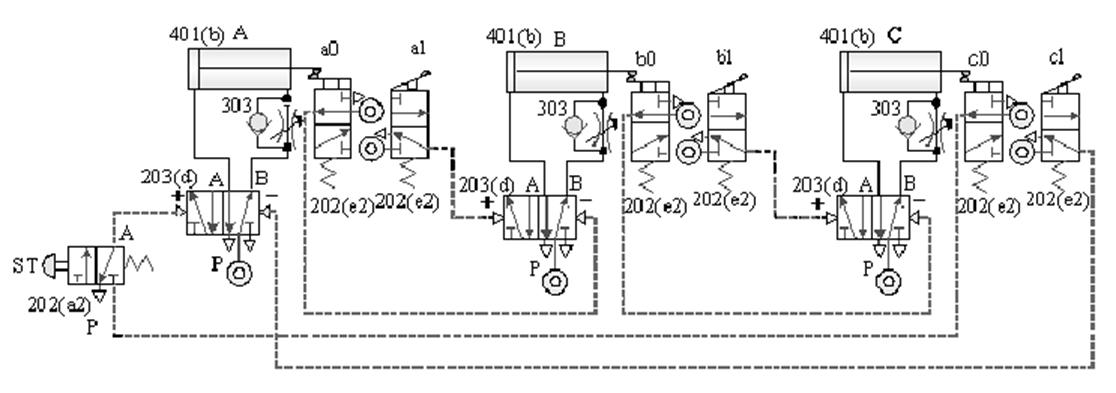

C. Three-cylinder sequential action circuit

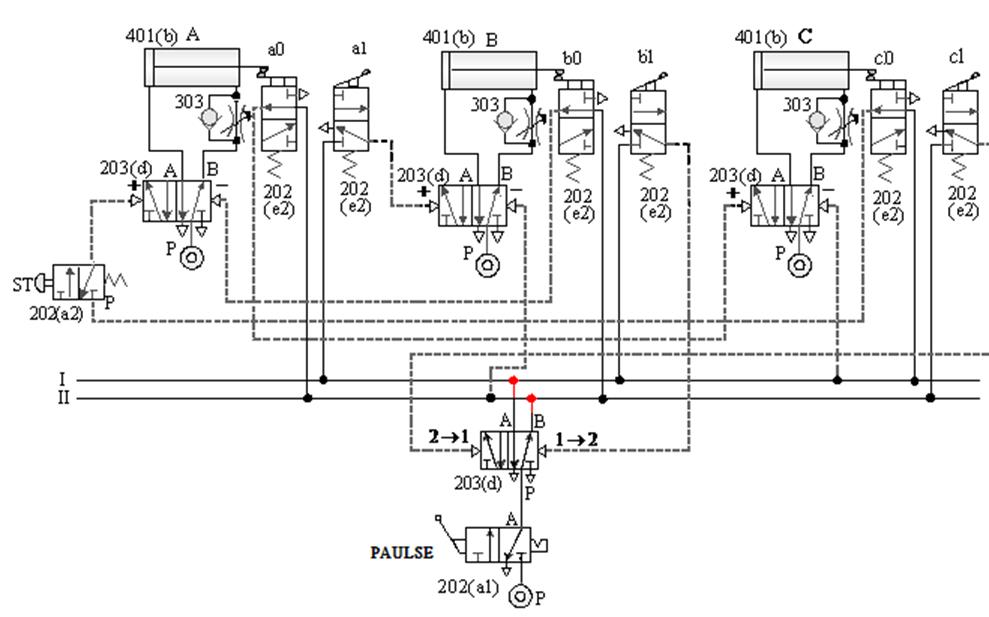

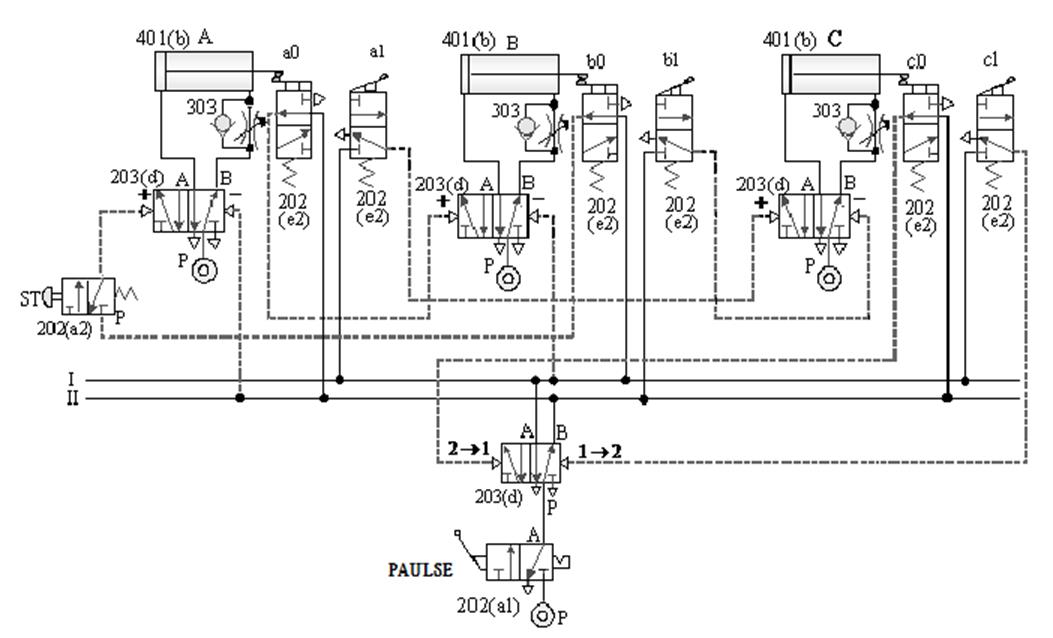

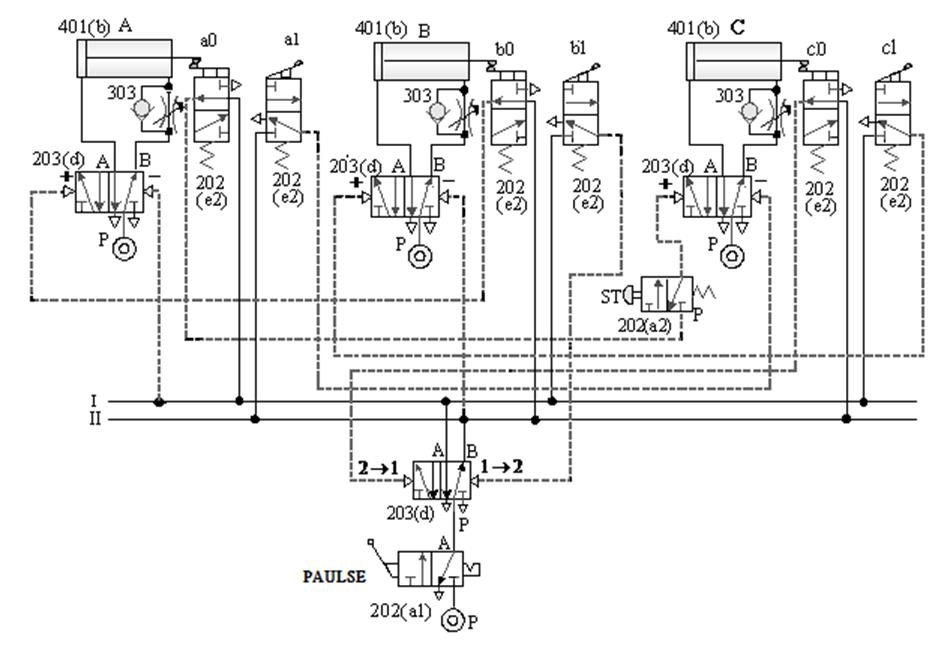

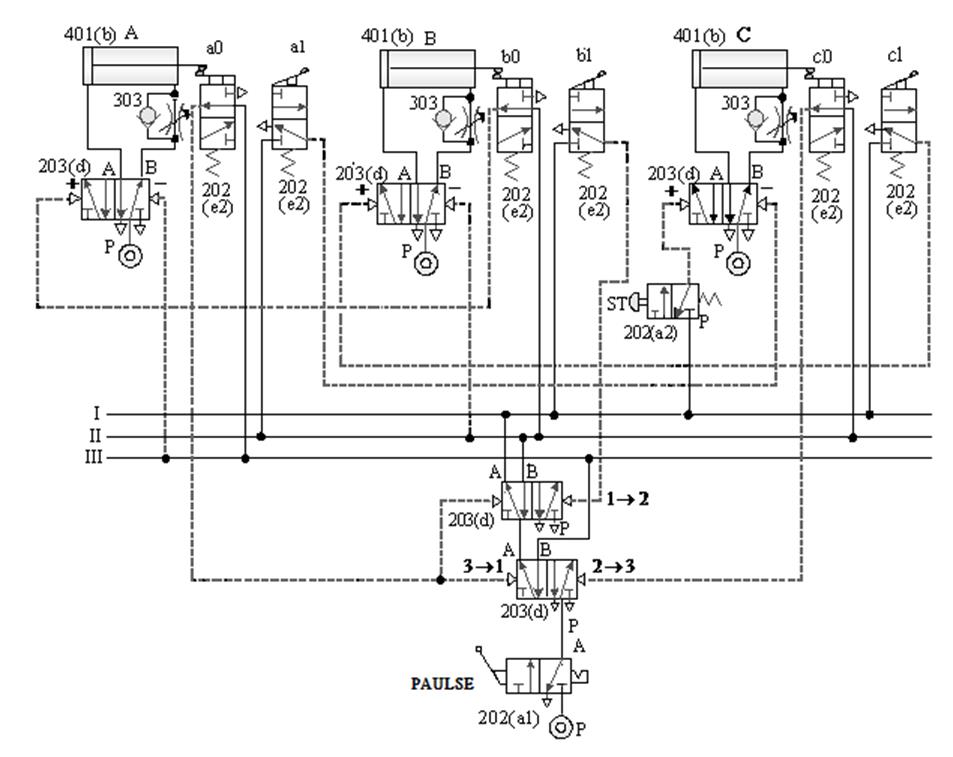

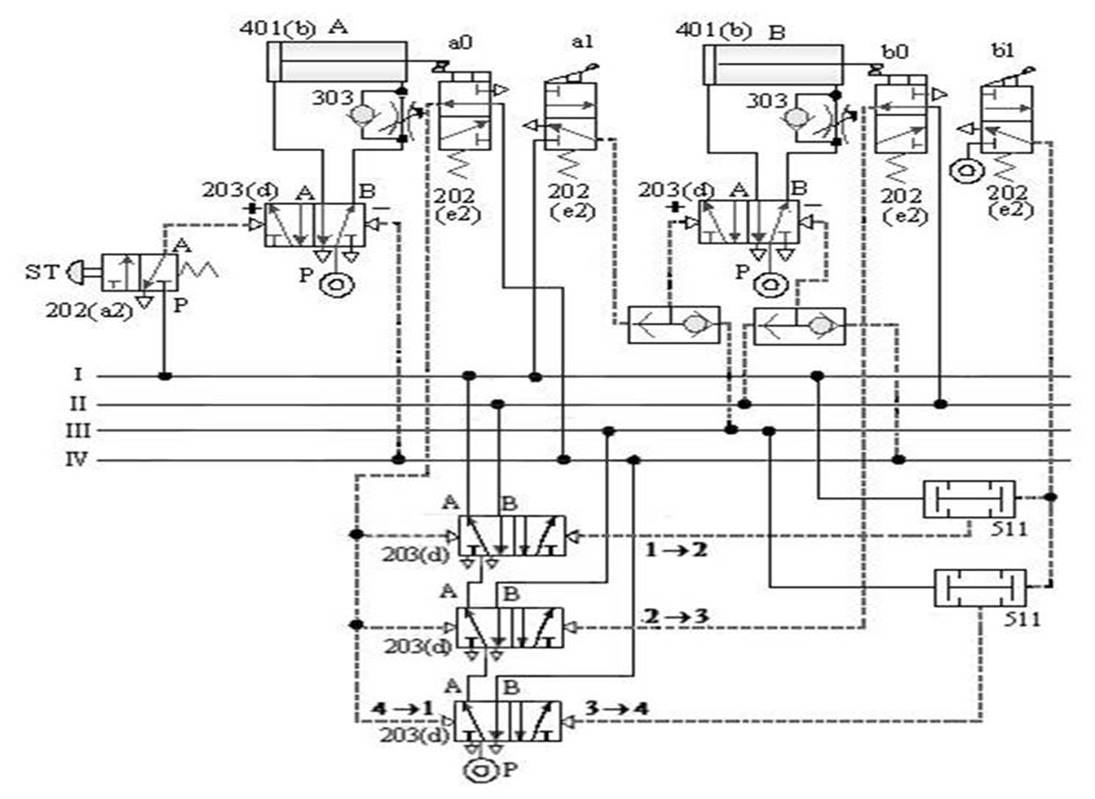

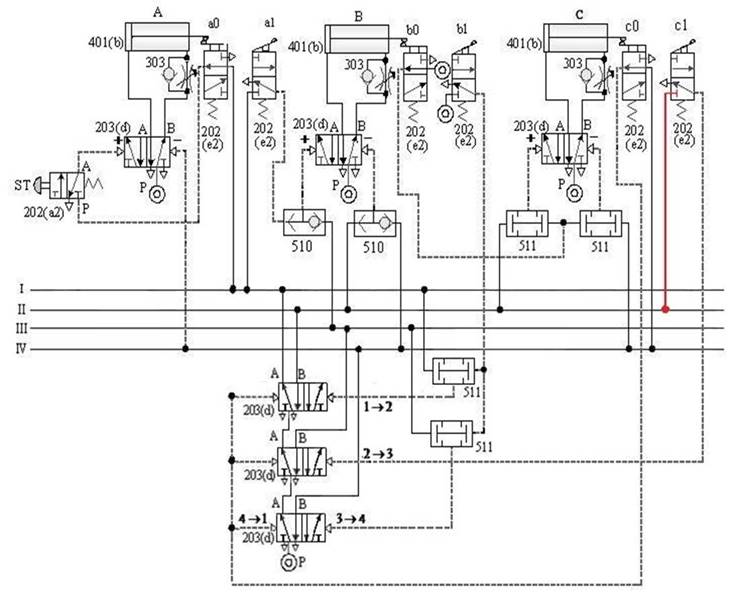

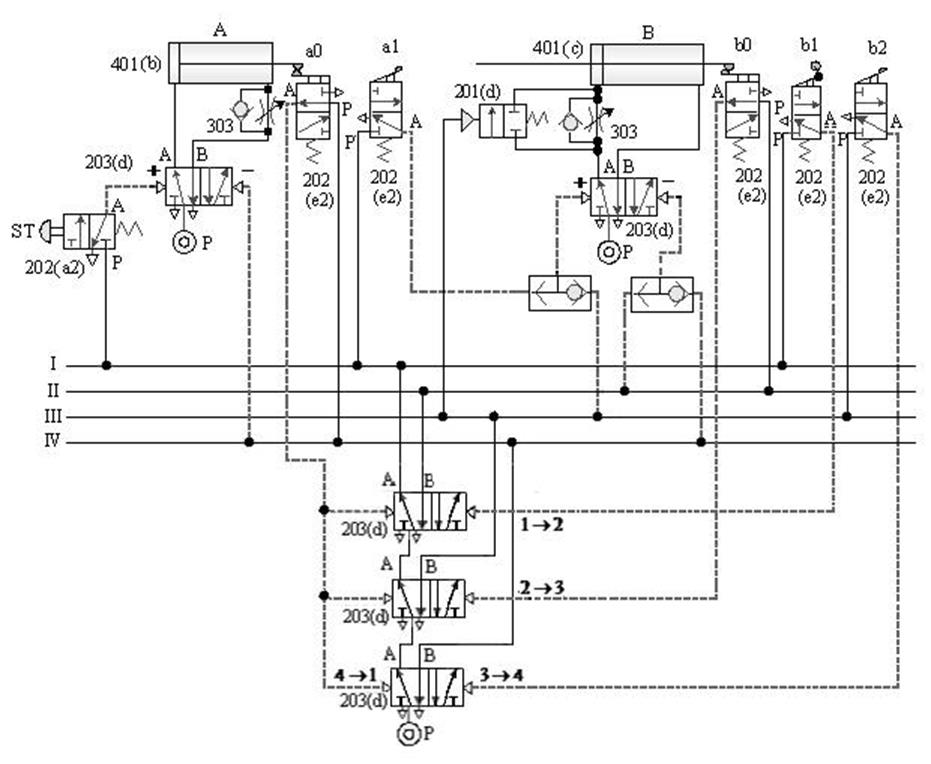

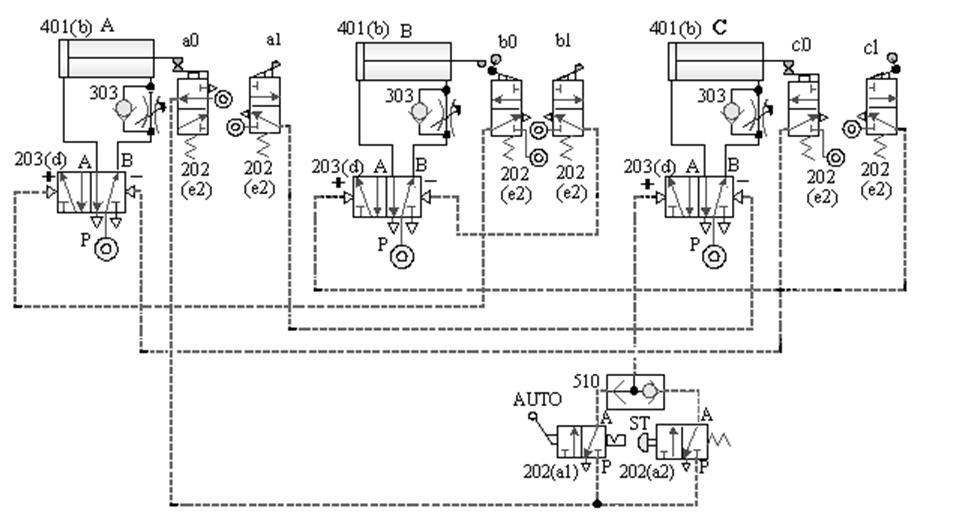

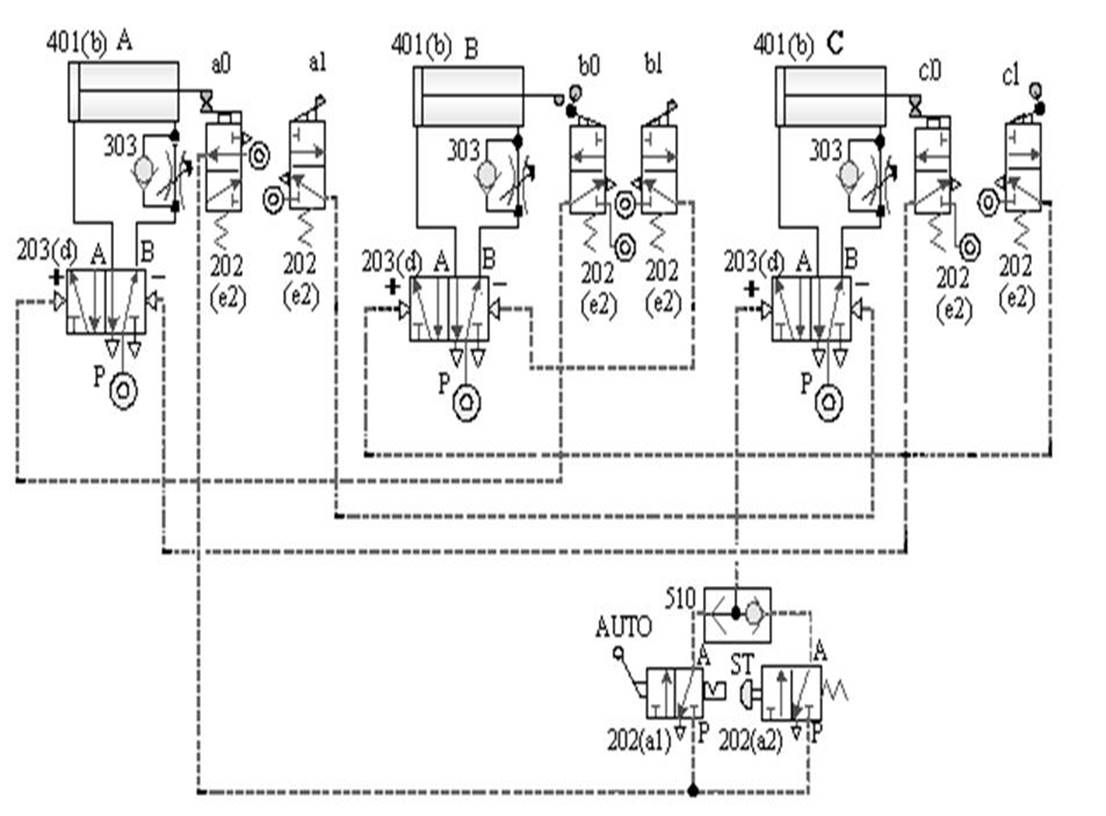

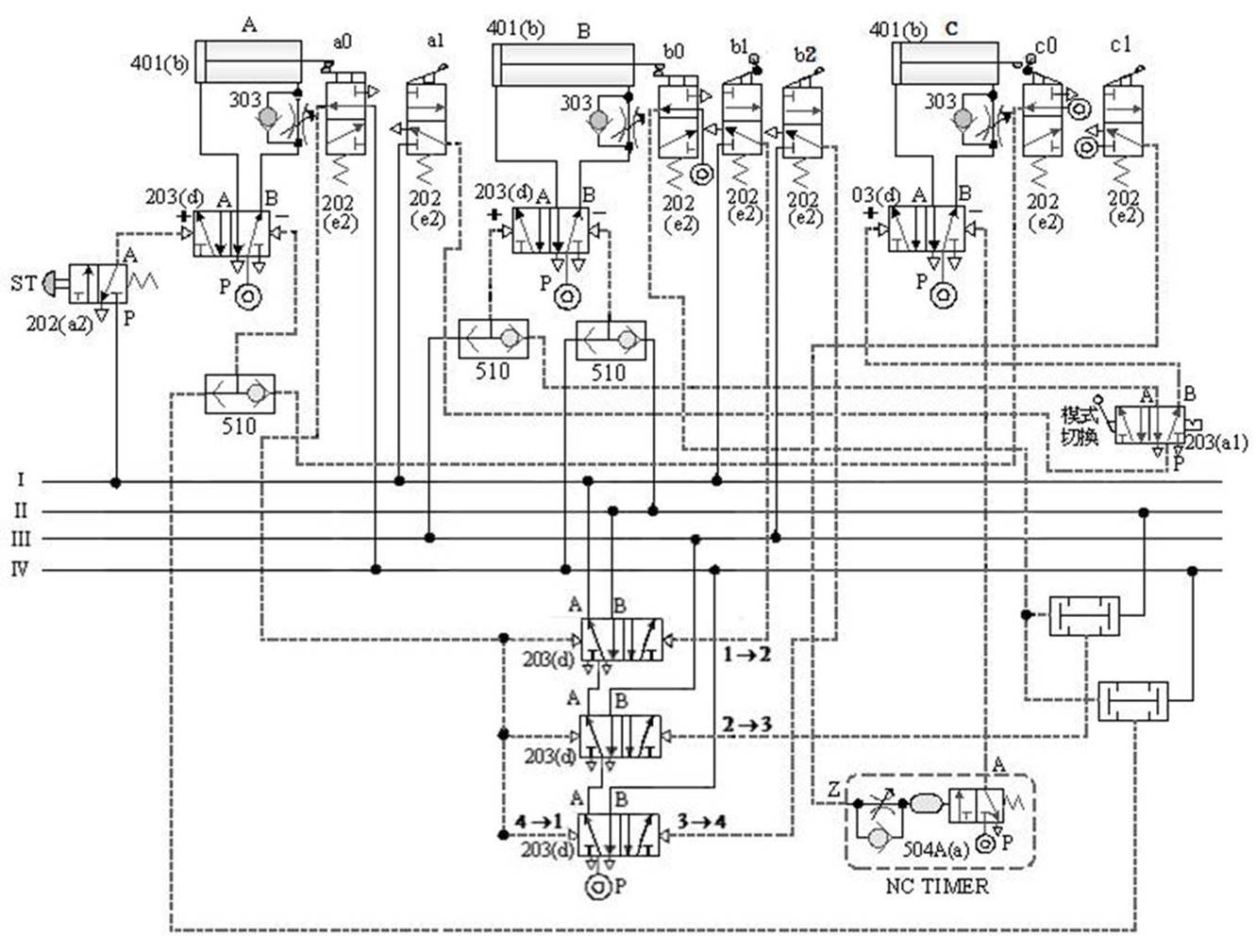

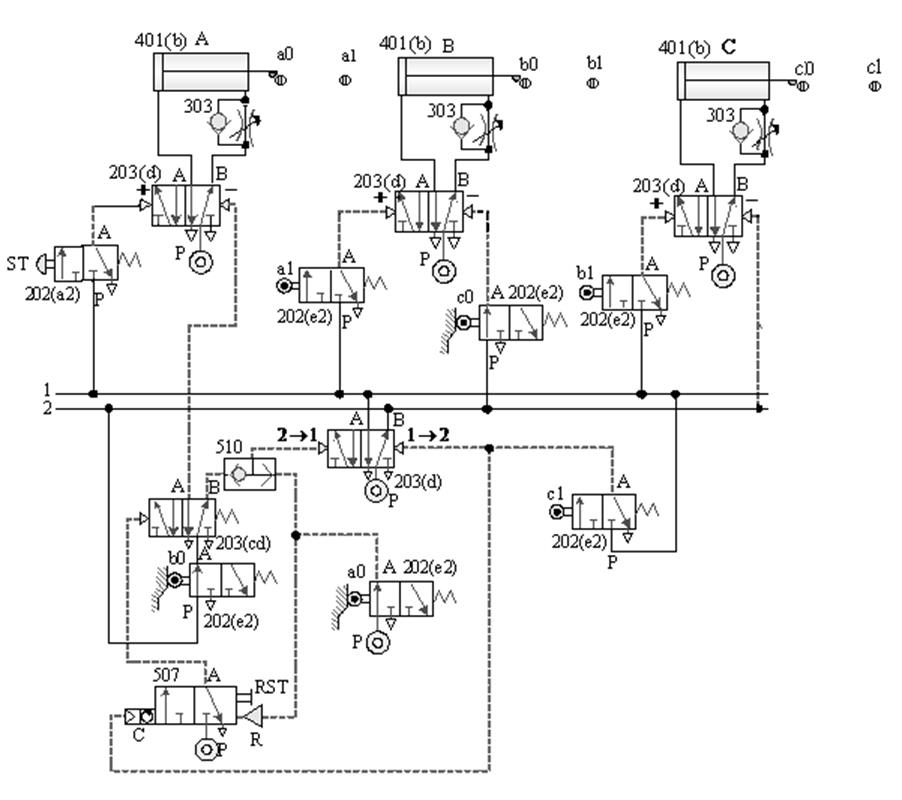

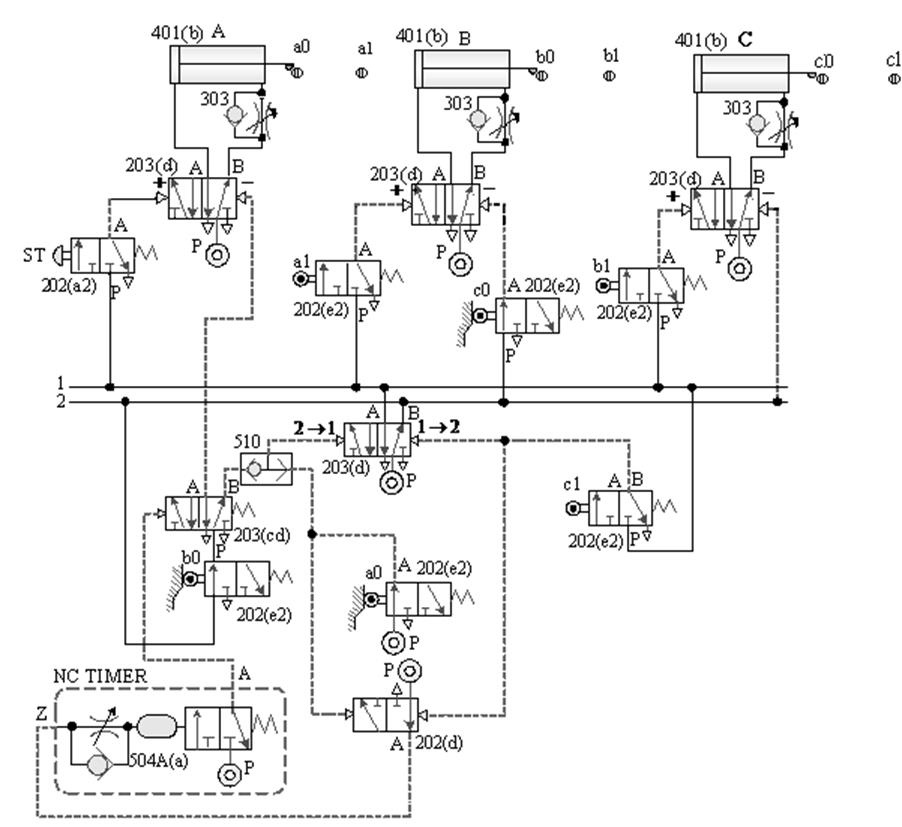

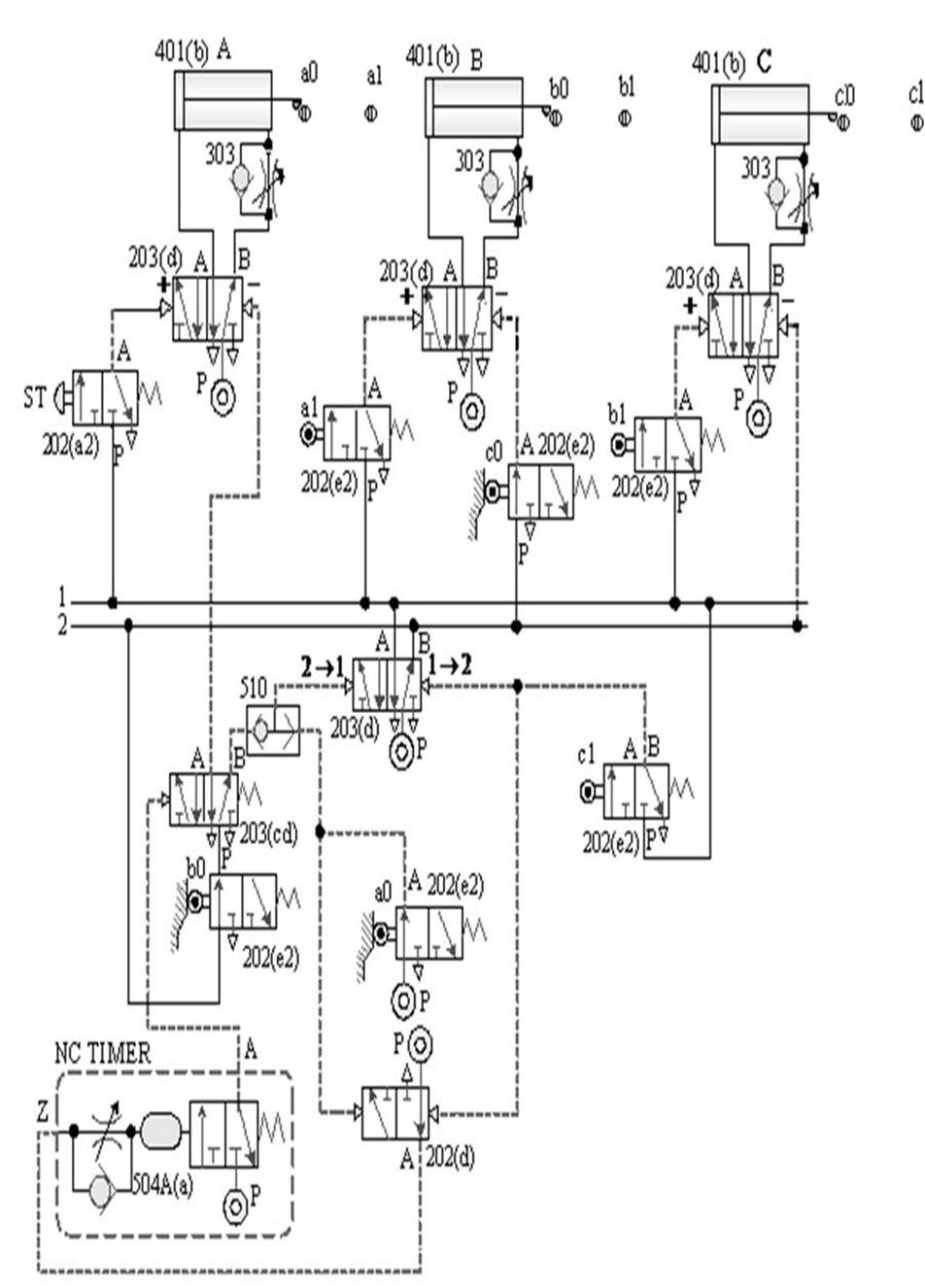

1-4-2 Sequence control --- three-cylinder cascade sequence action loop

The purpose of the practice: the three pneumatic

cylinders cooperate with the roller valve and the pilot valve for sequential

actions.

A. Three-cylinder cascade sequential action

circuit -1

B. Three-cylinder cascade sequential action

circuit -2

C. Three-cylinder cascade sequence action

loop -3

D. Three-cylinder cascade sequence action

loop -4

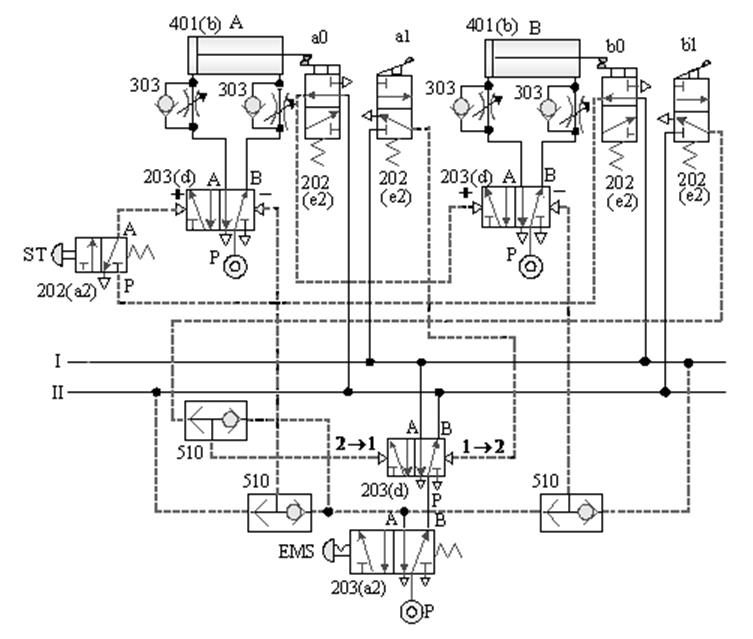

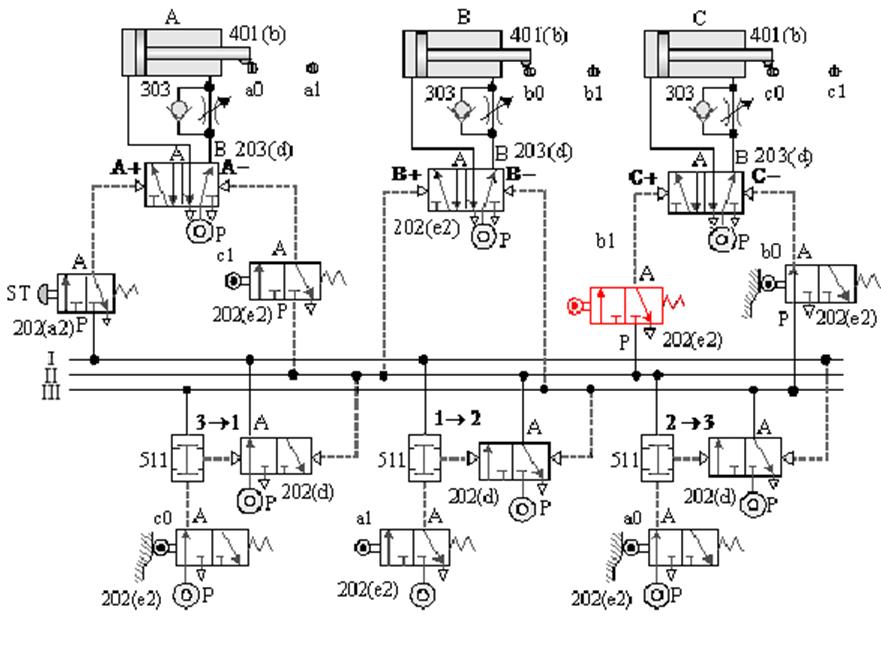

1-4-3 Sequential control -- Three

double cylinder cascade emergency s return control loop

Practice purpose: Two pneumatic cylinders

cooperate with roller valve, pneumatic pilot valve and 5/2 pressing ( hold ) button valve for emergency s return sequence

action control.

1-4-4 Sequence Control --- Repetitive Action Control Loop

The purpose of practice: Use two pneumatic

cylinders and roller valves to control the repeated actions of

cylinder B.

A. Double cylinder repetitive

action control circuit -1

B. Three cylinder repetitive action control circuit -2

1-4-5 Sequence Control --- Two-stage action control loop

The purpose of the practice: to control the

two-cylinder two-stage movement with the cascade method.

1-4-6 Sequence Control --- Circular Step Sequence Control Loop

The purpose of the practice: to do the

sequential action of the loop with three pneumatic cylinders in conjunction

with the cycle step method.

A. Cycle step sequence control loop -1

1-4-7 Speed control --- Two-stage speed control loop

Practice objective: Two-stage speed action

control of cylinder B with two pneumatic cylinders and a check throttle valve .

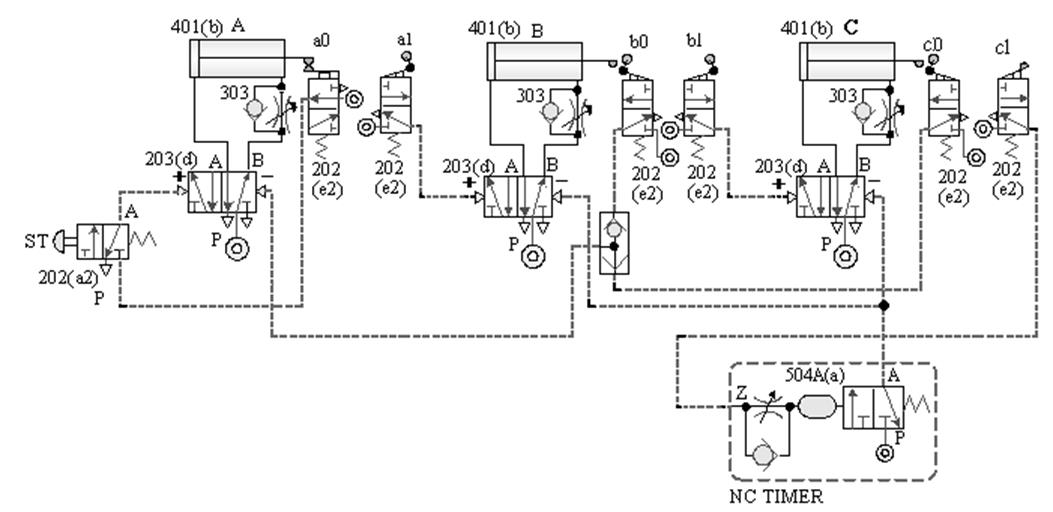

1-4-8 Timing control --- delay valve timing loop

The purpose of practice: to use three pneumatic

cylinders with delay valve and roller valve for timing control.

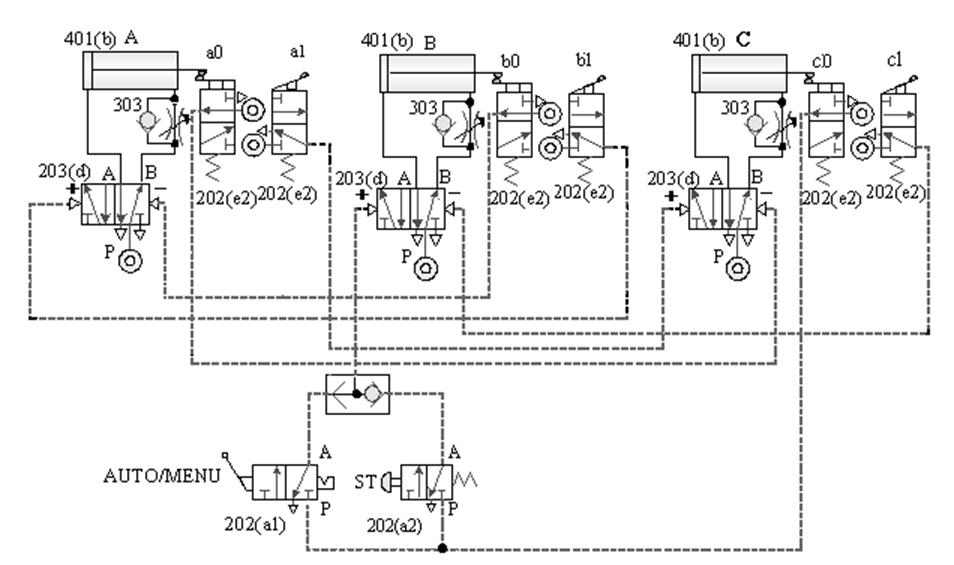

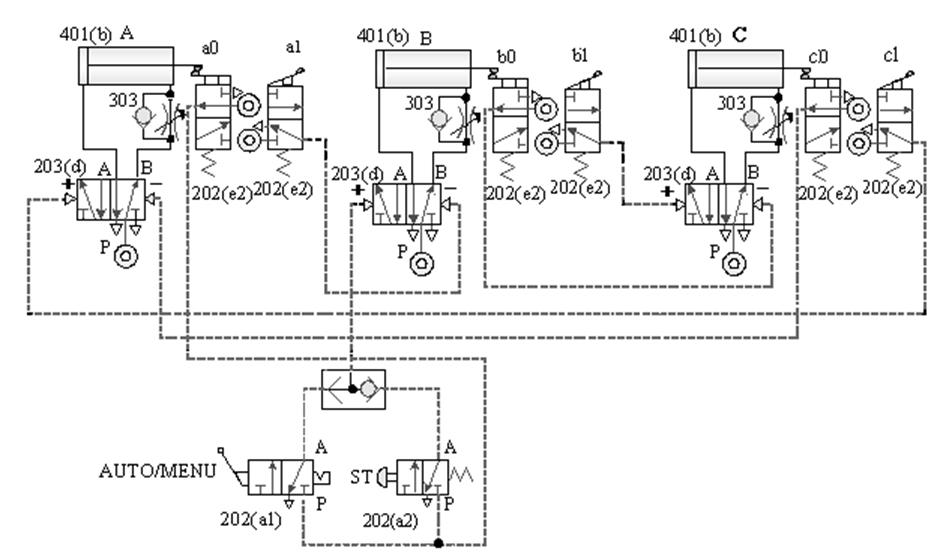

1-4-9 Manual automatic control --- three-cylinder manual / automatic sequence action loop

The purpose of the practice: the three-pneumatic

cylinder and roller valve cooperate with manual automatic control for

sequential actions.

A. Three-cylinder manual / automatic sequence action circuit -1

B. Three-cylinder manual / automatic sequence action circuit -2

C. Three-cylinder manual / automatic sequence action loop -3

1-4-10 Comprehensive control --- timing, parallel control loop

The purpose of practice: three pneumatic

cylinders cooperate with timing and counting valve to do the counting sequence

of the loop.

1-4-11 Comprehensive control --- timing, parallel progress, selection

control loop

The purpose of practice: three pneumatic

cylinders cooperate with timing and counting valve to do the counting sequence

of the loop.

1-4-12 Comprehensive control --- timing, parallel progress, selection, jump control loop

The purpose of practice: three pneumatic

cylinders cooperate with timing and counting valve to do the counting sequence

of the loop.

ˇ@

1-4-13 Counting control --- three-cylinder counting control loop

Purpose of practice: Three pneumatic cylinders

cooperate with counting valve to do the counting sequence of the circuit.

1-4-14 Comprehensive control --- timing and counting control loop

The purpose of practice: three pneumatic cylinders

cooperate with timing and counting valve to do the counting sequence of the

loop.

1-4-15 Comprehensive control --- counting + mode selection control loop

Purpose of practice: Three pneumatic cylinders cooperate

with counting valve to do the counting sequence of the circuit.

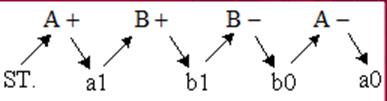

[1] The relationship between the switching signal

and the touch: the touch between the pneumatic cylinder and the roller valve during the movement stroke and

the signal switching relationship.

Taking A+B+B - A - as an example, the diagram of the relationship

between the switching signal and the touch is as follows:

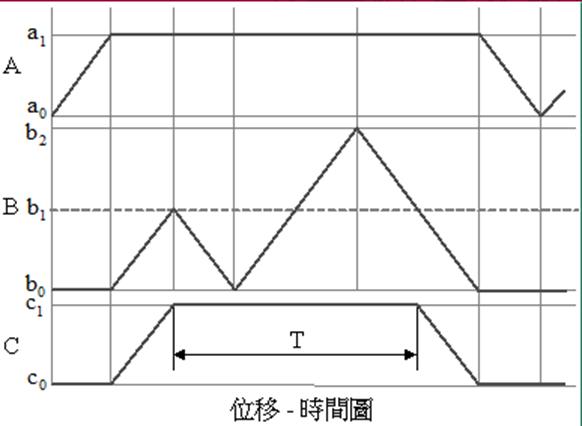

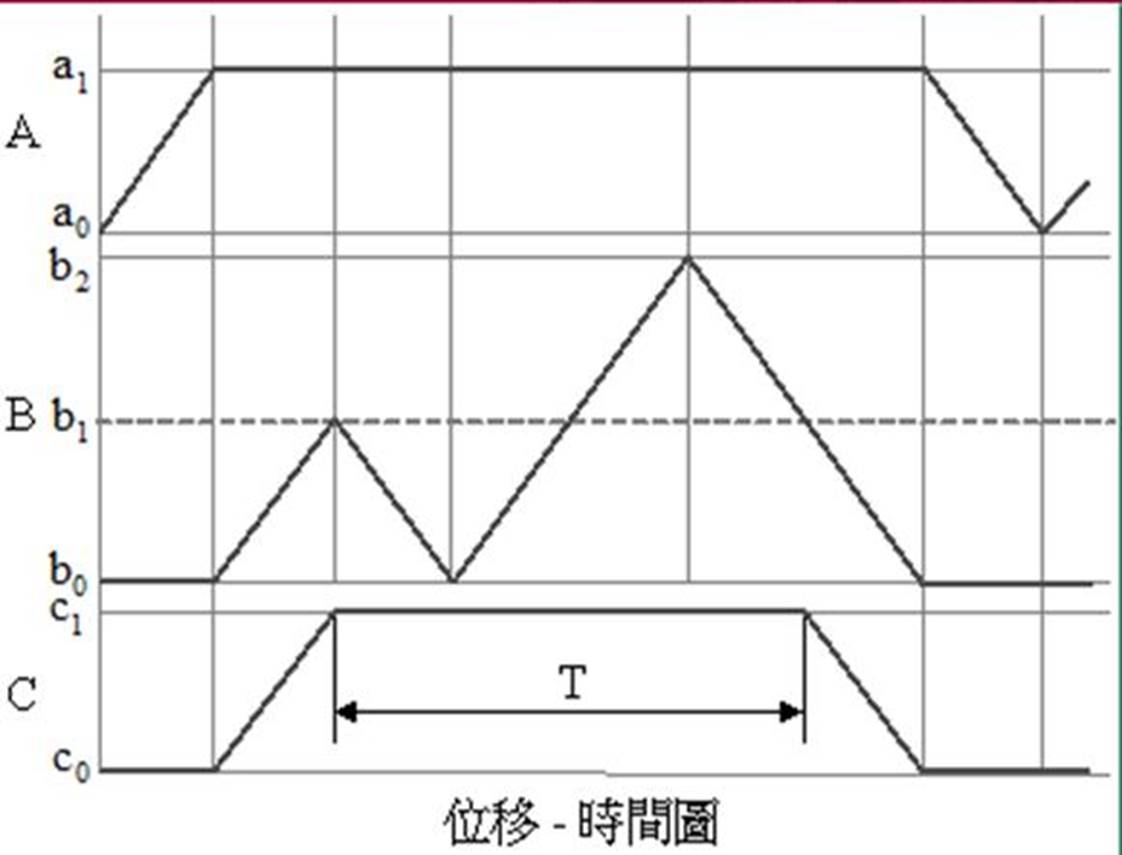

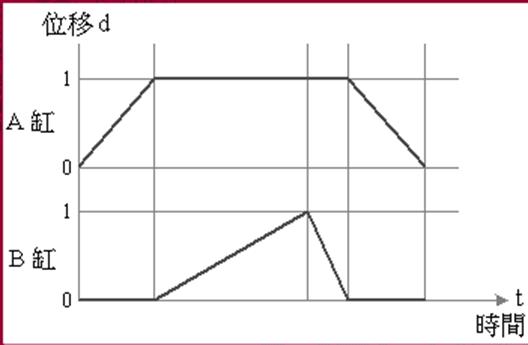

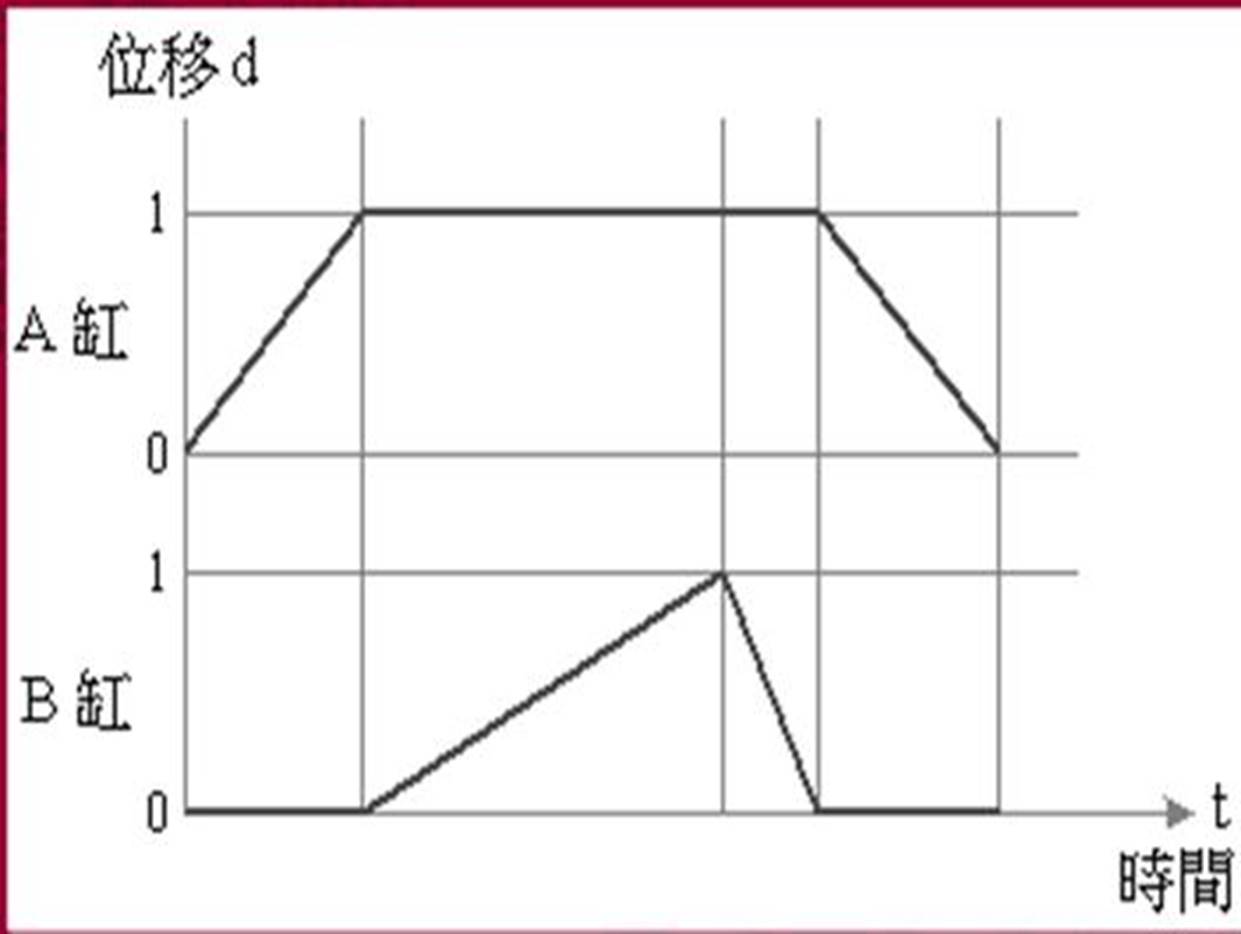

[2] Displacement - time graph: a graph indicating the action state of the pneumatic

cylinder. In the figure, the horizontal axis is time, the vertical axis is

displacement, and the slope is speed.

Taking A+Bslow+B - A - as an example, the B cylinder is slow out and fast back, and the displacement - time diagram is as follows:

***************************************************************************************************************************************************************

ˇ@

ˇ@

Appendix Pressure Opening

ˇ@

A. Room

pressure

ˇ@

ˇ@

ˇ@

ˇ@