?

1. Before

operation, adjust the flow rate of all speed control valves to the

minimum; reset the timer and counter to zero; and check whether there is

water in the three-piece combined filter cup.

If so, loosen the bolt at the bottom of the cup to drain water and adjust

the pressure to .

2.

When wiring

and piping, the power supply and Pneumatic source should be turned

off to avoid

danger and component damage caused by electric shock or pipe explosion.

3.

When connecting

or disconnecting the circuit, hold the connector end and

do not

pull the wire ,

so as not to damage the internal copper wire.

4.

The unused

components and pipelines on the machine platform should be placed

properly and don't fall to the ground.

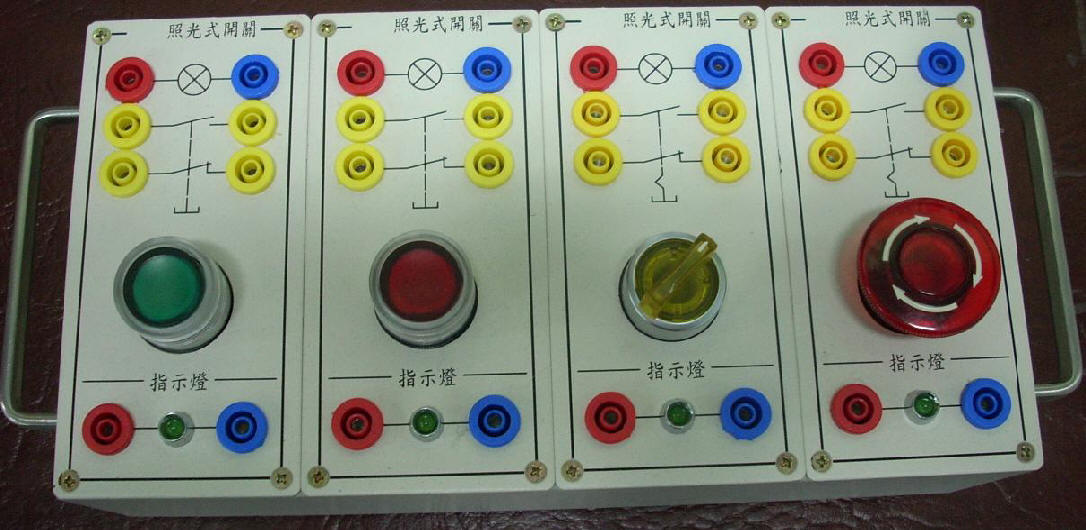

5. If

the power cord is suspected to be disconnected, you can switch the

three-purpose meter to the ohm range for measurement; or connect the

power supply to the indicator light to confirm.

6.

The power

cords should be sorted

and neatly sorted according to their lengths ,

and they should not be tangled or tangled.

After use, put the power cords of the same length together and put them

in place.

7.

When wiring,

you should follow the order of the electrical ladder diagram from left

to right, up and down ,

and donЁІt jump in randomly.

So as not to cause wiring inaccuracy and increase the trouble of

checking the line.

8.

After the Pneumatic and electrical circuits are connected properly, turn on the pressure

source and power

switch and start

the circuit.

If you cannot move or move incorrectly, turn off the Pneumatic and

power switch before making corrections to the circuit.

9. If

there is still no power after turning on the power, confirm whether

there is a short circuit. And check whether the overload

protection is tripped or the fuse is

burned out?

If there

is a possibility of a short circuit, the power should

be turned

off first ,

and the power can

be turned on after removing

the short circuit and obstacles .

10. If

the same

contact appears repeatedly in the loop , separate

wiring and avoid sharing terminals to

reduce the occurrence of short circuits or error signals.

And pay

attention to the order of the wiring of the contacts to avoid short

circuit caused by the connection of the live

wire (+) and

ground wire (-) .

11.

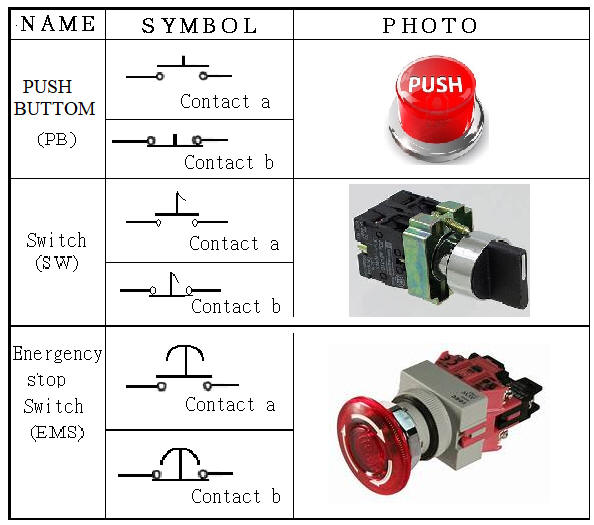

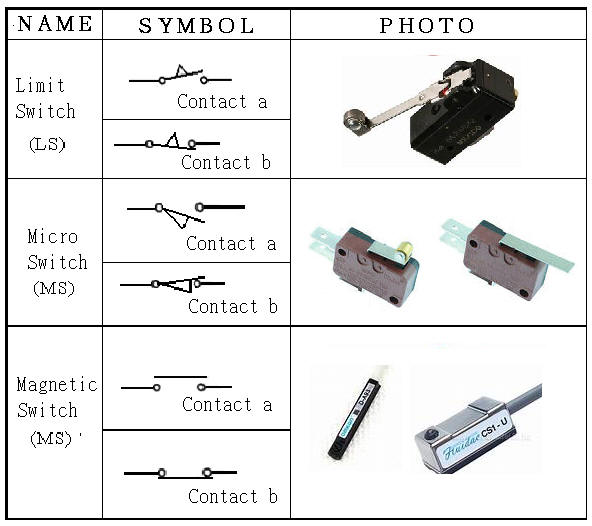

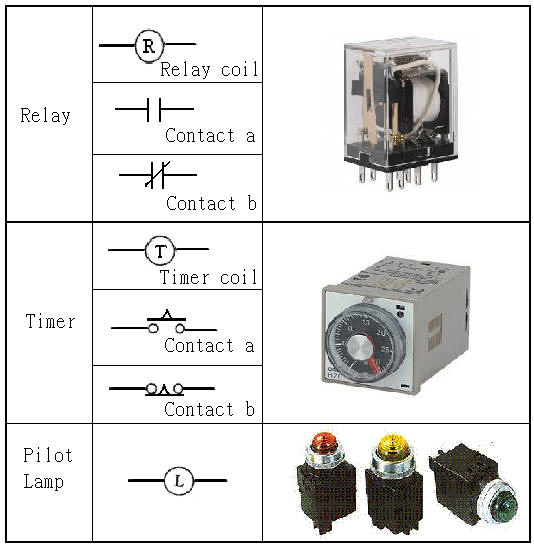

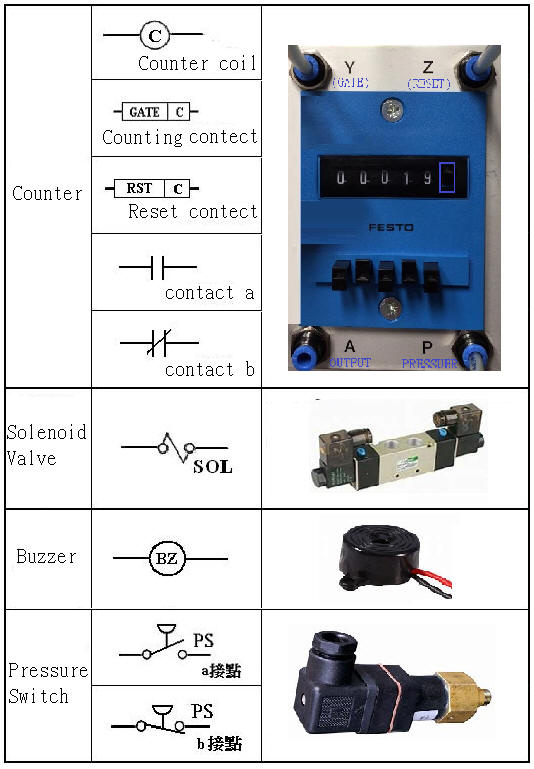

NO normally

open contact (Normally

Open Contact) that

is a contact

point

( Usually

it is open circuit without power, after switching, it is closed circuit

with power ) ,

NC normally

closed contact (Normally

Closed Contact) is the b contact

( Usually

it is closed-circuit energized, after switching, it becomes open-circuit

without energization ) .

12. After

all the operation is completed, should be closed

and the power pressure source and receipt

of the pressure tube and the power supply line, cleaning placement table ,

and indeed

fill usage history table .

Ё@

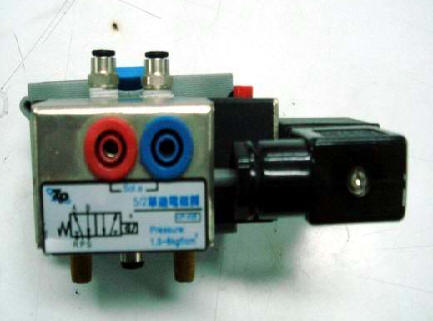

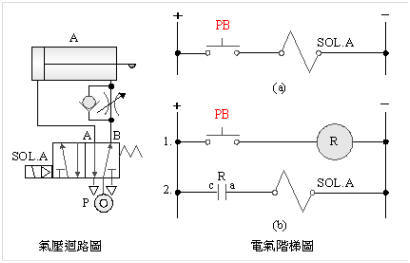

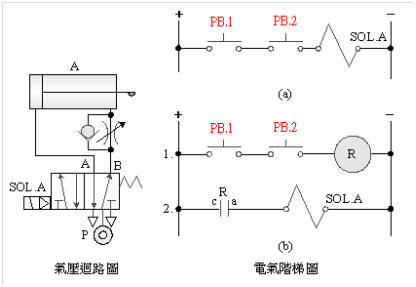

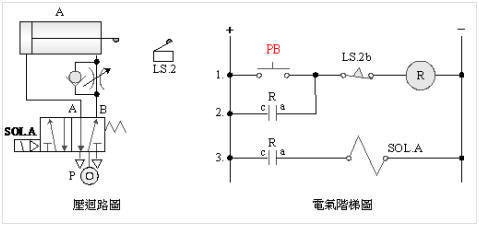

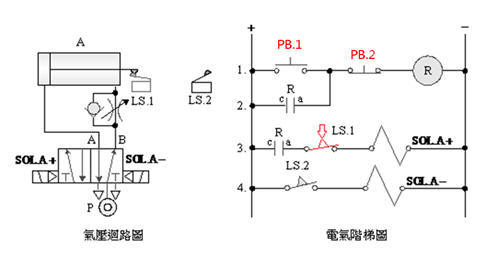

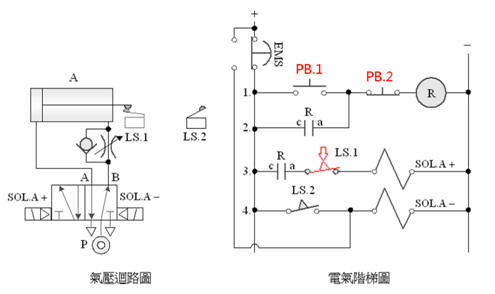

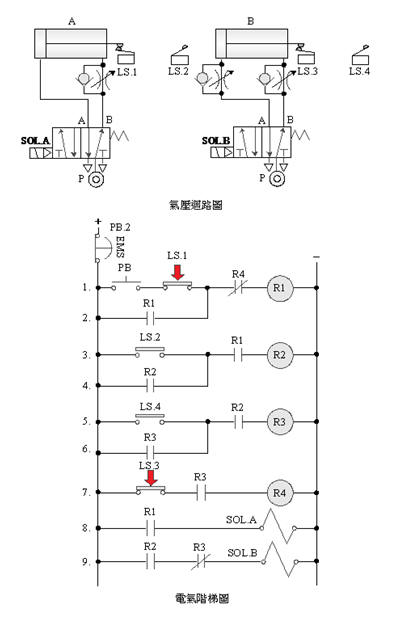

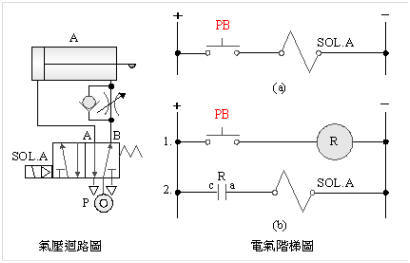

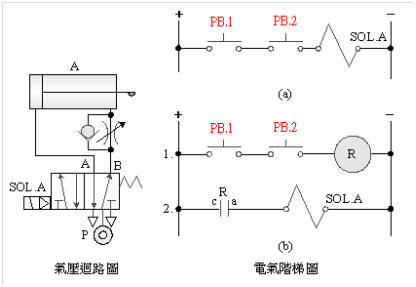

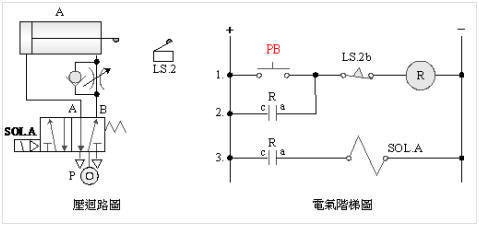

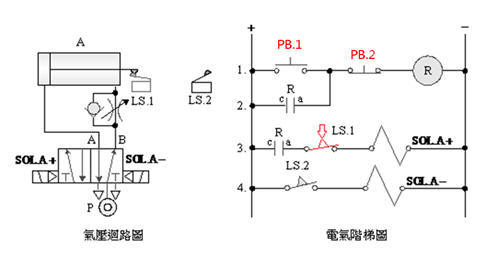

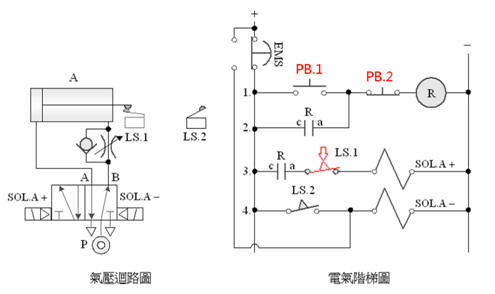

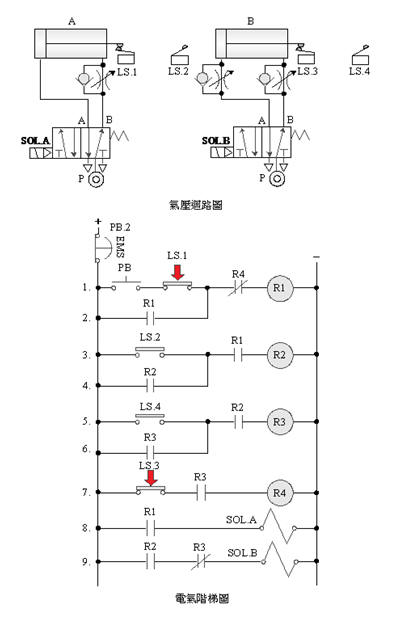

2-3-1Ё@single

solenoid valve control circuit

Internship

purpose: to understand the

operating principle of 5/2 single

solenoid valve.

Use

circuit:

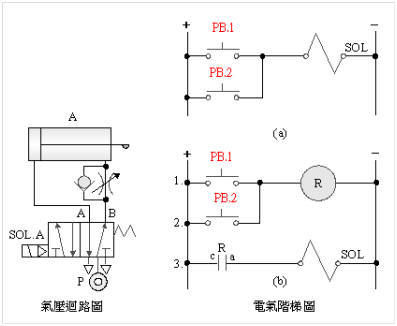

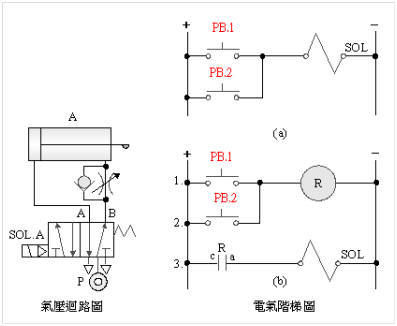

2-3-2Ё@Self-protection ( memory ) control

circuit

Internship

purpose: to understand the operation principle of self-protection

circuit.

Use

circuit:

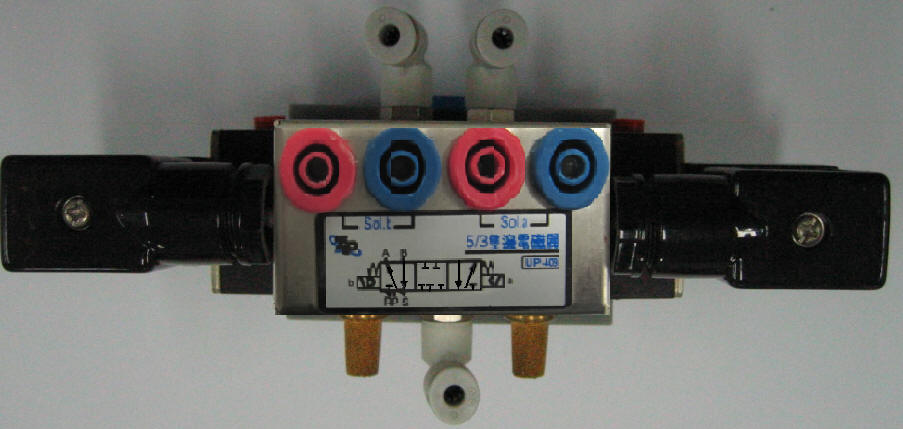

2-3-3Ё@Double

solenoid valve control circuit

Practice

purpose: to understand the principle of operation of dual solenoid

valves.

Use

circuit:

A. 5/2 double

solenoid valve

B. 5/3 neutral

double solenoid valve

C.5/3 Neutral

Air Intake Double Solenoid Valve

2-3-4Ё@series

and parallel control loop

Practice

purpose: to understand the operation principle of series and parallel

circuits.

Use

circuit:

A. Series

circuit

B. Parallel

circuit

2-3-5Ё@Interlock ( Priority ) Control

Circuit

Practice

purpose: to understand the

operation principle of the interlock ( priority ) control

circuit.

Use

circuit:

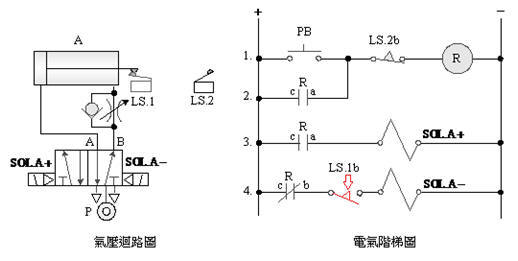

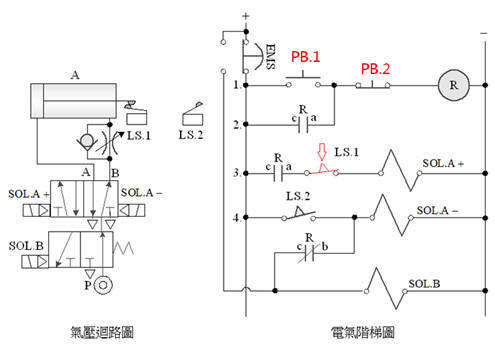

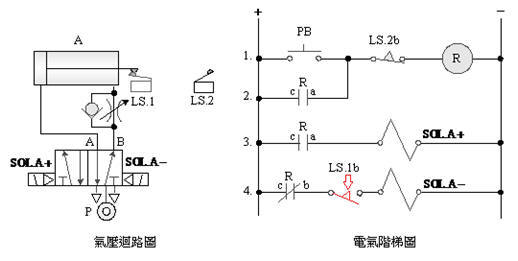

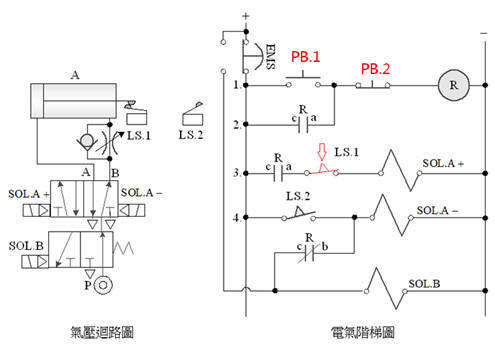

2-3-6Ё@One

reciprocating control loop

Internship

purpose: understand the function of memory circuit and limit switch and

the application of automation.

Use

circuit:

A. 5/2 single

solenoid valve

B.

5/2 double

solenoid valve

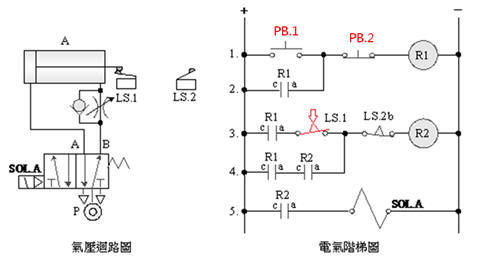

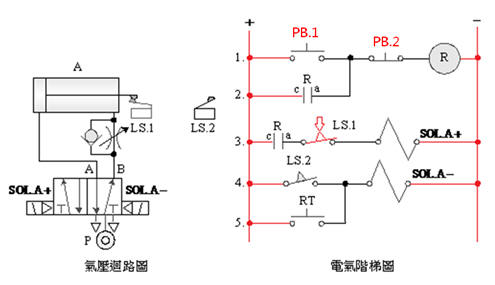

2-3-7 Continuous

reciprocating control loop

Internship

purpose: understand the function of memory circuit and limit switch and

the application of automation.

Use

circuit:

A. 5/2 single

solenoid valve

B. 5/2 double

solenoid valve

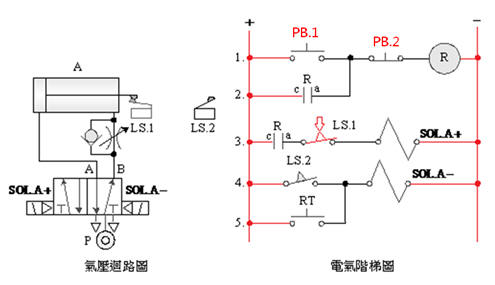

2-3-8Ё@Delay

control loop

Internship

purpose: to understand the

function of Timer .

Use

circuit:

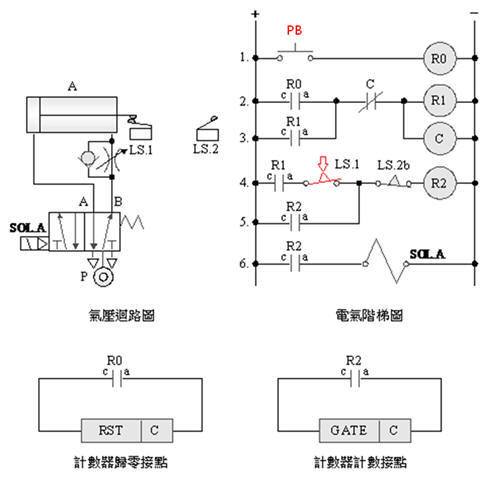

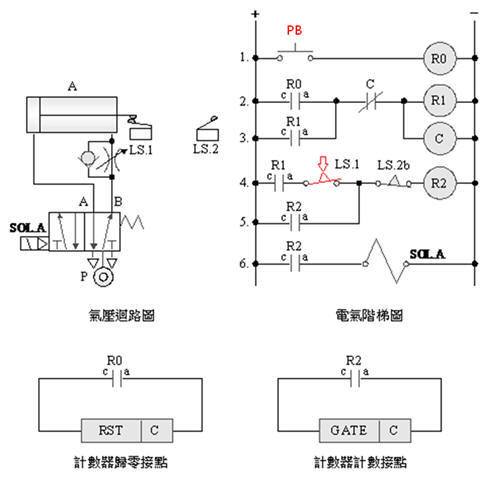

2-3-9Ё@counting

control loop

Internship

purpose: to understand the

function and application of the counter (Counter) .

Use

circuit:

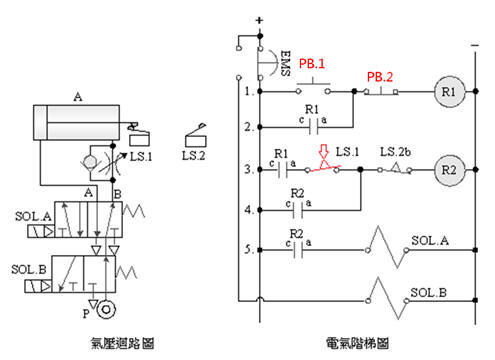

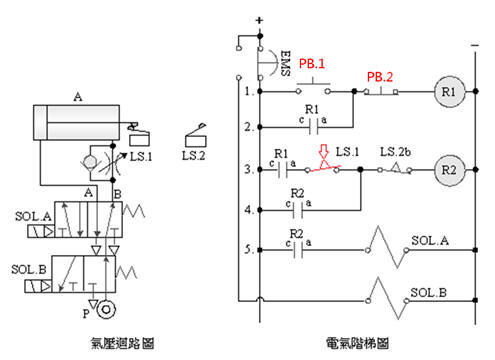

2-3-10Ё@Emergency

s homing control loop

Internship

purpose: understand 5/2 emergency

s homing control.

Use

circuit:

A. Single

solenoid valve emergency s homing control

B. Single

solenoid valve returns to position after emergency s is released

C. Double

solenoid valve emergency s homing control

D. Double

solenoid valve returns after emergency s is released

2-3-11Ё@Emergency

s and move to the end control loop

Practice

purpose: to understand the function of 5/2 double

solenoid valve emergency s moving to the end control.

Use

circuit:

2-3-12Ё@Single

button ON/OFF control

circuit

Internship

purpose: to understand how to achieve the function of power switch with

a single button.

Use

circuit:

2-3-13Ё@Load

balancing control loop

Practice

Objective: Learn how to 2 Ke 5/2 single

solenoid valve with the relief valve reaches the intake bilateral

attached load balancing function.

Use

circuit:

A.

5/2 single

solenoid valve load balance control

B. 5/3 dual

solenoid valve load balance control

2-3-14 Load

lock control circuit

Practice

Objective: Learn how to 2 Ke 5/2 single

solenoid valve with bilateral guide intake valve reaches annexed locking

function.

Use

circuit:

A. 5/2 single

solenoid valve load lock control

B.

5/3 dual

solenoid valve load lock control

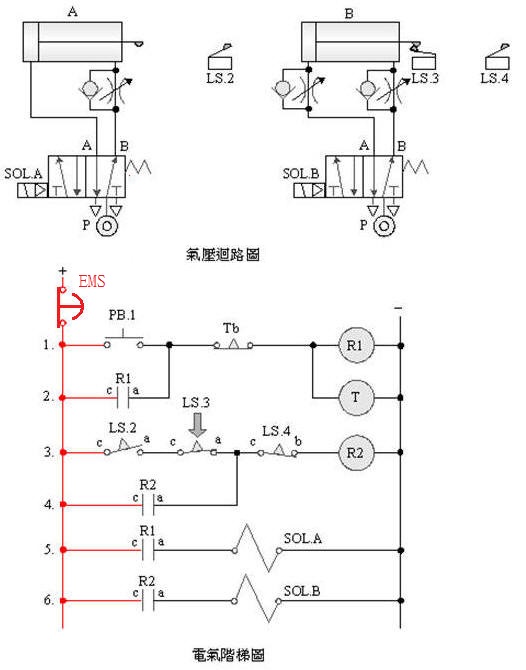

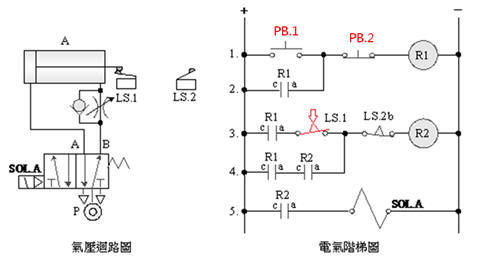

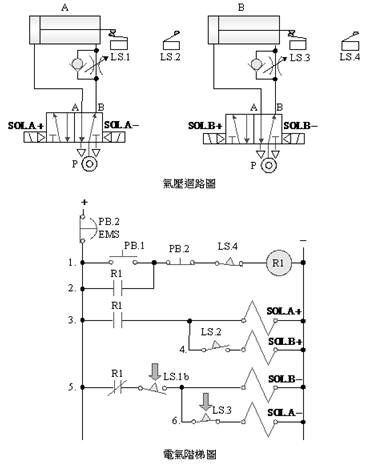

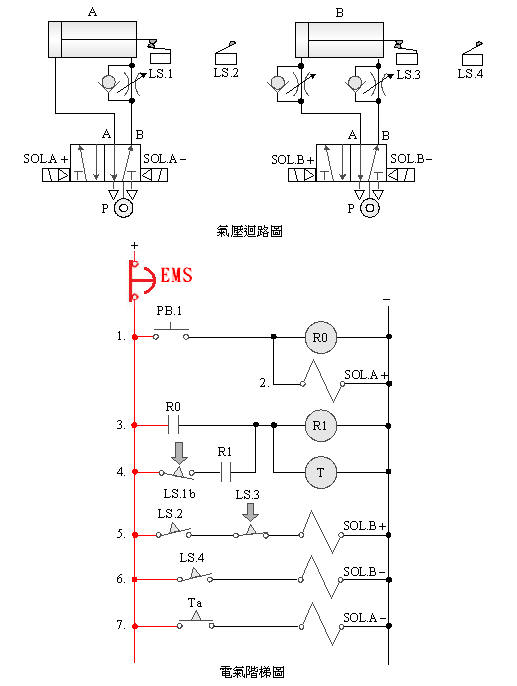

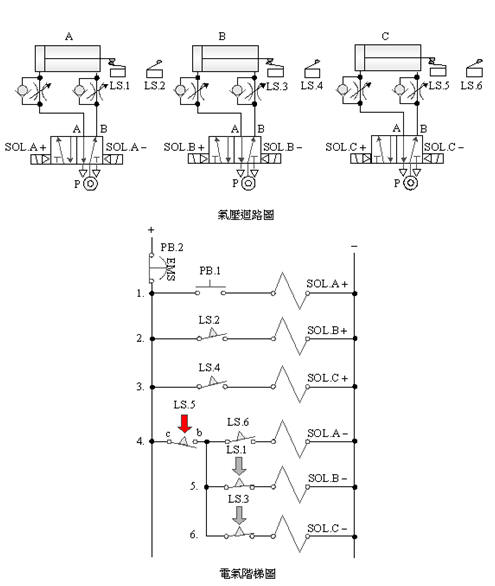

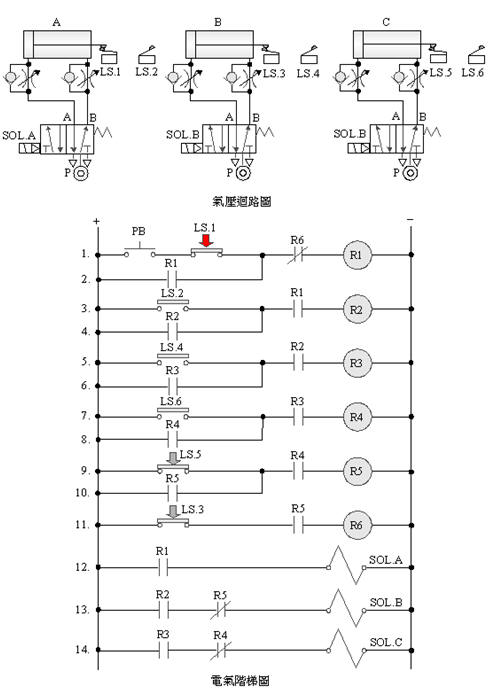

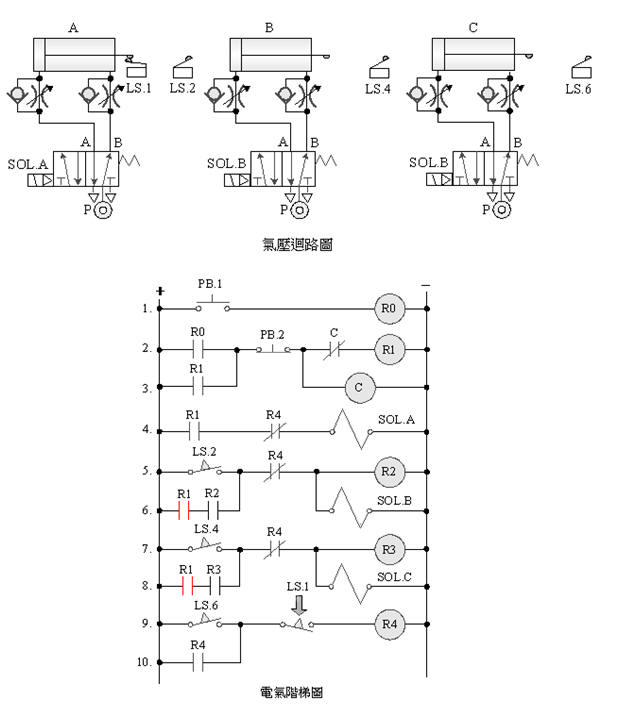

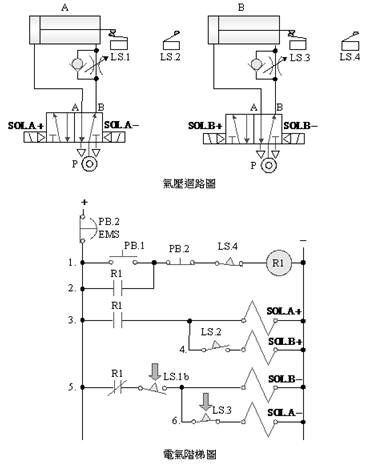

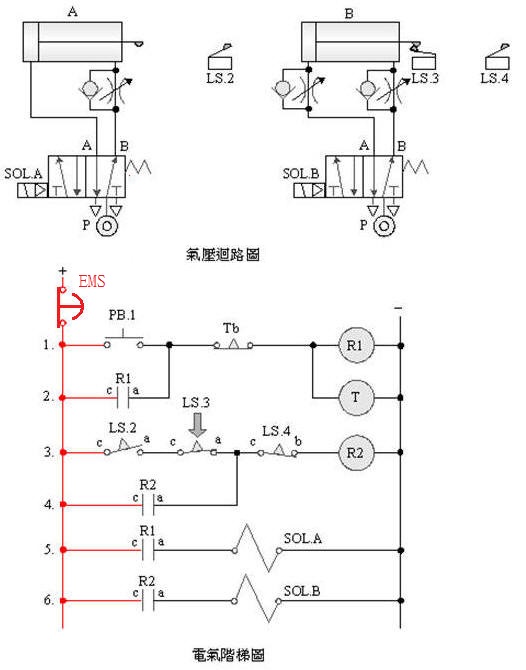

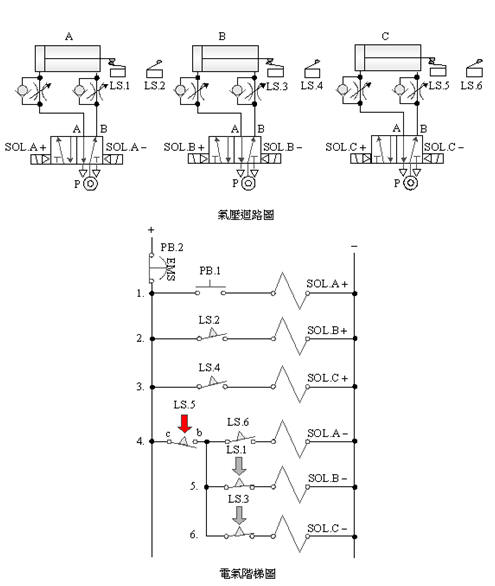

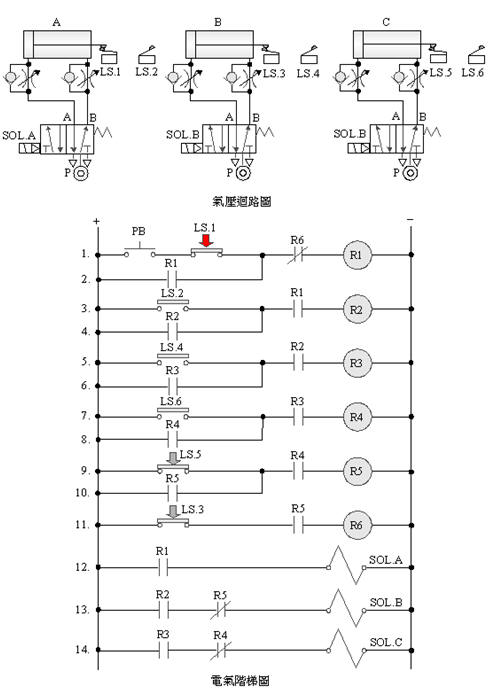

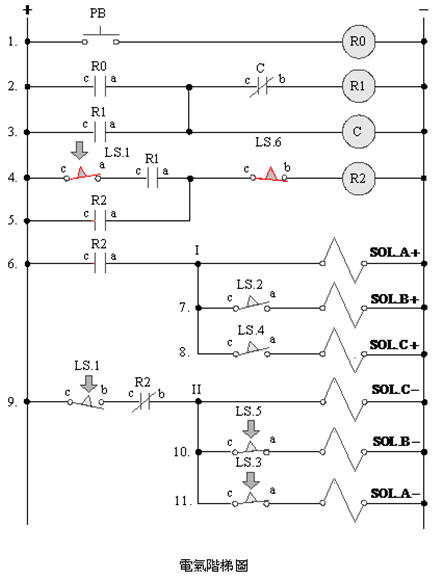

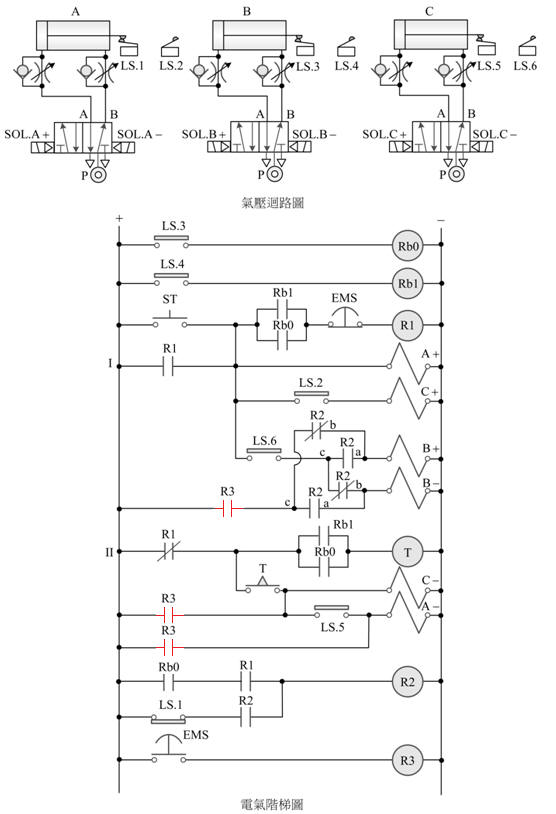

2-4-1

DoubleЁ@-cylinder

sequential action control circuit

The

purpose of the practice: to use solenoid valve with limit switch and

electrical circuit for sequential control of double pneumatic cylinders.

Use

circuit:

A.

5/2 single solenoid

valve sequence control

B. 5/2 double

solenoid valve double cylinder sequence action control

C. 5/2 single

solenoid valve double cylinder sequential action control

D. 5/2 double

solenoid valve double cylinder sequence action control

E.

5/2 single

solenoid valve double cylinder sequential action control

F.

5/2 double

solenoid valve double cylinder sequence action control

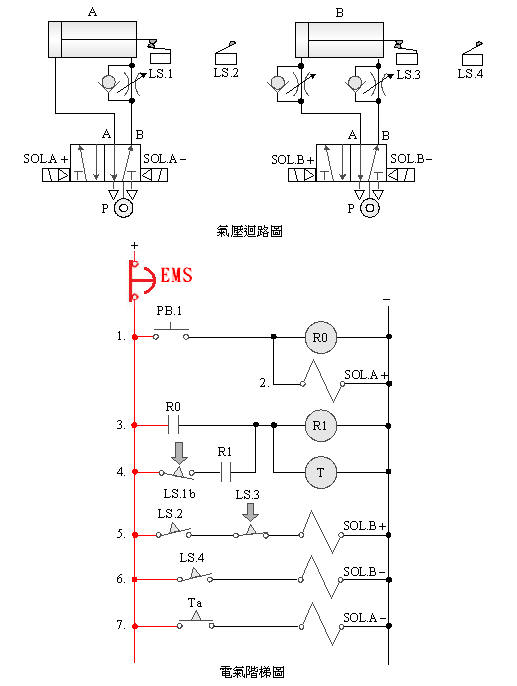

2-4-2Ё@Delay

sequence control loop

The

purpose of practice: to control the time delay sequence with double

pneumatic cylinder solenoid valve, limit switch, timer and electrical

circuit.

Use

circuit:

A. 5/2 single

solenoid valve delay control

B.

5/2 double

solenoid valve delay control

2-4-3Ё@Delayed Repeat Action

Control Circuit

The

purpose of the practice: to control the sequence of time-delayed

repetitive actions by using double pneumatic cylinders with solenoid

valves, limit switches, timers and electrical circuits.

Use

circuit:

A.

5/2 single

solenoid valve time-delay iterative control

B.

5/2 double

solenoid valve time-delay repetitive control

2-4-4Ё@Counting

sequence control loop

The

purpose of the practice: to control the sequence of time-delayed

repetitive actions by using double pneumatic cylinders with solenoid

valves, limit switches, timers and electrical circuits.

Use

circuit:

2-4-5 single

solenoid valve three-cylinder sequence action, delay, emergency return

loop

The

purpose of the practice: to use three pneumatic cylinders with 5/2 single

solenoid valve, limit switch, timer and EMS emergency

s button for sequential action, delay and emergency return control.

Use

circuit:

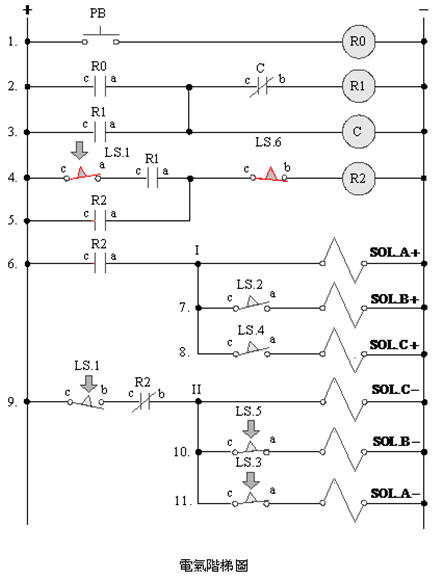

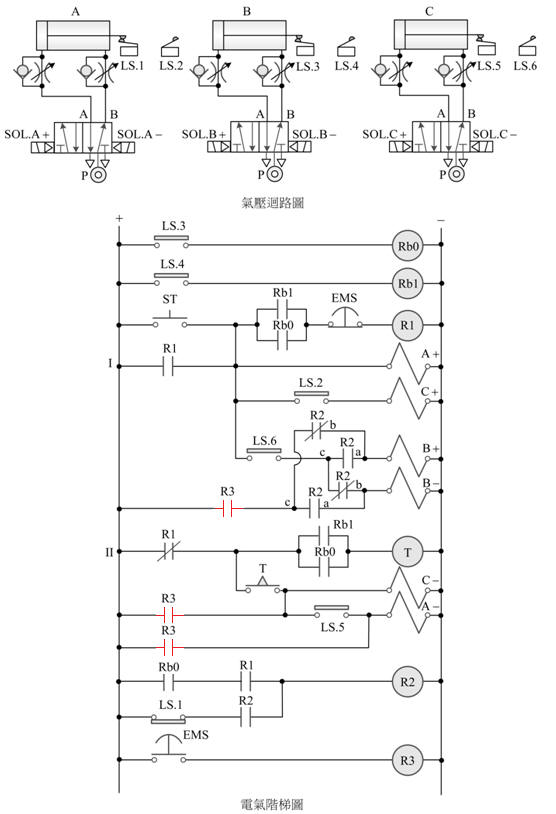

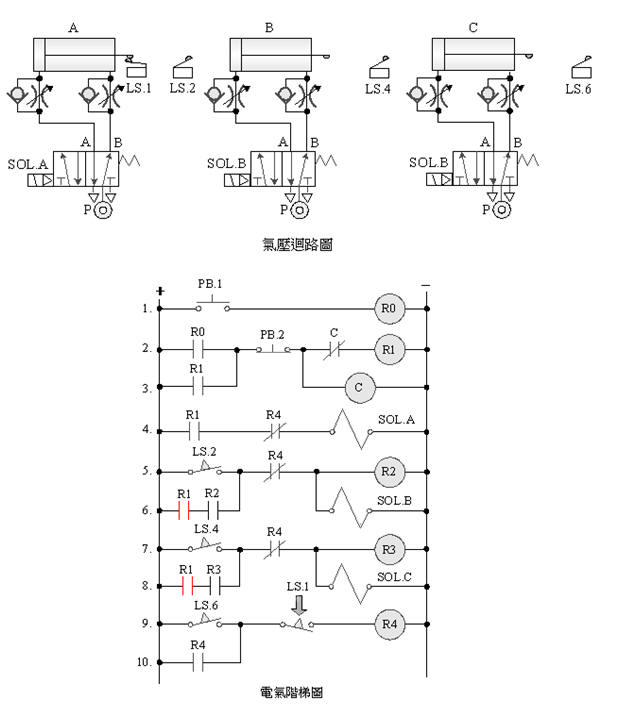

2-4-6Ё@Double

solenoid valve triple cylinder sequence action reverse sequence return

circuit after emergency s

Internship

purpose: Use three pneumatic cylinders with 5/2 double

solenoid valves, limit switches and EMS emergency

s buttons to do sequential actions and reverse sequence return control

after emergency s.

Use

circuit:

2-4-7Ё@Single

solenoid valve three-cylinder sequence action emergency s return circuit

The

purpose of practice: To control

the sequence delay action with three pneumatic cylinders

with 5/2 single

solenoid valve, limit switch and electrical circuit.

Use

circuit:

2-4-8 Double

solenoid valve triple cylinder sequence action emergency s stroke to the

end to continue action control circuit

The

purpose of the practice: Use three pneumatic cylinders with 5/2 double

solenoid valves, limit switches, and electrical circuits for sequential

actions to continue the action control after the emergency s stroke is

released to the end.

Use

circuit:

2-4-9Ё@Single

solenoid valve three-cylinder sequence action emergency s synchronous

homing control loop

The

purpose of the practice: use three pneumatic cylinders with 5/2 single

solenoid valve, limit switch and electrical circuit for emergency s

synchronous return control.

Use

circuit:

2-4-10 double

solenoid valve three cylinder timing control circuit

The

purpose of the practice: use three pneumatic cylinders with 5/2 double

solenoid valves, limit switches, timers and electrical circuits for

timing control.

Use

circuit:

2-4-11Ё@Single

solenoid valve three-cylinder sequential action circuit

The

purpose of the practice: to control

the sequence action with three pneumatic cylinders with 5/2 single

solenoid valve, limit switch and electrical circuit.

Use

circuit:

2-4-12Ё@double

solenoid valve three cylinder counting control loop

The

purpose of practice: to use three pneumatic cylinders with 5/2 double

solenoid valves, limit switches, counters and electrical circuits for

counting control.

Use

circuit:

2-4-13Ё@Single

solenoid valve three cylinder counting sequence action circuit

The

purpose of the practice: To control

the sequence counting action with three pneumatic cylinders

with 5/2 single

solenoid valve, limit switch, counter and electrical circuit.

Use

circuit:

Ё@

2-4-14Ё@three-cylinder

two-stage non-return action circuit

The

purpose of the practice: Two-stage

non-return sequence action control with three pneumatic

cylinders with 5/2 single

solenoid valve, limit switch and electrical circuit.

Use

circuit:

[1] Relation

between switching signal and touch: the

touch and signal switching

relationship between the pneumatic

cylinder and the roller valve during the movement stroke.

Taking A+B+B - A - as

an example, the diagram of the relationship between the switching signal

and the touch is as follows:

Ё@

[2] Displacement - time

graph: A graph

indicating the action state of the pneumatic cylinder. In the figure,

the horizontal axis is time, the vertical axis is displacement, and the

slope is speed.

Take Aslow+B+tB - A - as

an example, the B cylinder

is slow out and fast back, and the displacement - time

diagram is as follows:

Ё@

Ё@

Ё@