Chapter 5 Electrical-Pneumatic Control

Goto Zulie teacher teaching network Pneumatic hydraulic control practice

5-1 Electrical control element P193

5-1-1 Electrical switch (Electrical Switch) P194

There are three types of switch contacts: ¡§ a¡¨ contact, ¡§ b¡¨ contact, and ¡§ c¡¨ contact.

¡@

5-1-2 the Push-the Button Switch, PB P 194 the

5-1-3 the Toggle Switch, TS) P197 the ¡@

Tilt (DIP) switch DIP switch

¡@

5-1-5¡@Pilot Lamp P199 the

Is

generally more commonly used indicator color: (1) Red :indicates

the machine is in operation;(2) Green :indicates

the machine s condition;(3) White:Indicates

power ;(4) yellow :

warning indication, fault.

¡@

https://hyauto.en.ec21.com/Pilot_lamp--557655_557717.html

5-1-6 Sensor P199 ¡@

The most commonly used sensors for sequence control

n 1. Limit Switch (LS) .

n 2. Photoelectric Switch (PHS) .

n 3. Proximity Switch (PXS) .

n 4. Pressure switch (PS)

¡@

5-1-7 Limit Switches (LS) P200 the

The limit switch has NO normally open contact ( ie a contact ) , and NC normally closed contact (ie b contact ) and the common point (Com) . When the limit switch is not pressed, the Com point is connected to the NC contact. When pressed, the Com and NO contacts are closed.

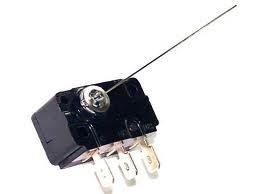

5-1-8 Micro Switch (MS) P202 the

5-1-9 Photoelectric Switch (PHS) P202

5-1-10 Proximity Switch (PXS) the P205 the

5-1-11 Pressure Switch (PS) P207

5-1-12 No Fuse Breaker (NFB) P207 the

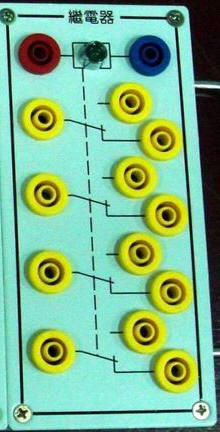

5-2 Electromagnetic Relay and Rlectromagnetic Contactor P210

5-2-1¡@Principle

of Electromagnetic Relay

¡@

Physical diagram of Electromagnetic Relay

5-2-4 Electromagnetic Magnetic Contactor (MC) P216 the

5-2-5 Thermal Relay (TH) P218 the

¡@

5-2-6 Magnetic switch (MS) the

5-5 COUNTER P223

5-6 Basic logic circuit with contacts P225

(1) YES

circuit ( Normal

phase circuit )

¡@

(2) NOT circuit ( Inverting circuit ) P226

(3) AND circuit ( Series circuit ) P226

(4) OR circuit ( Oarallel circuit ) P226

(5) Self-keep ( memory ) circuit P22 7

(6) Interlocking ( Priority ) circuit P227

5-7 Basic Electrical - Pneumatic Control Circuit P229

5-7-1 Control the forward and backward movement of the pneumatic cylinder by manual button

(1) Design

with single coil Solenoid valve P229

¡@

(2) design with double coil solenoid valve P231

5-7-2 Forward and backward movement of pneumatic cylinder controlled by timer

(1) Design

with single coil solenoid valve P232

¡@

(2) design with double coil solenoid valve P236

5-7-3 Automatic Forward and Backward Circuit of Pneumatic Cylinder ( Single Cycle )

(1) Design

with Single Coil Solenoid Valve P237

¡@

5-8 Electrical - Pneumatic

Application Circuit

P 242

Example 5-1 Design the electrical - pneumatic circuit diagram based on the displacement time diagram:

¡@

Join auxiliary status P247

Example 5-2 Tries to design the electric - pneumatic circuit diagram based on the following displacement step diagram: P255

¡@

design with single coil solenoid valve

Designed with dual coil solenoid valve P262

Electrical - pneumatic control circuit design example

GOTO Chapter 6 PLC Programmable Pneumatic Pressure Control

Goto Zulie teacher teaching network Pneumatic Hydraulic control practice