n1. The

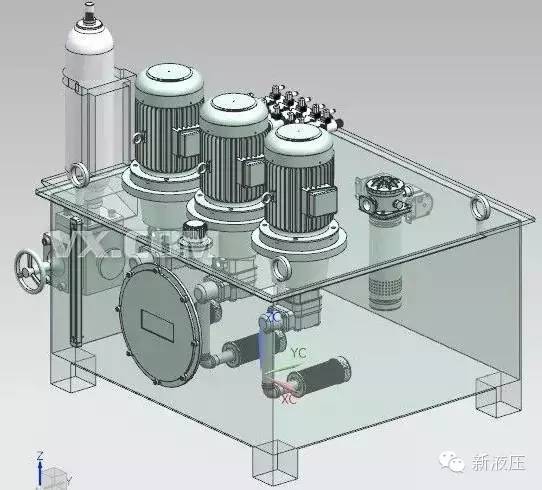

storage capacity of the hydraulic oil tank should be appropriate, as shown

in Table 2-1 ,

the hydraulic

oil tank

The

capacity should be more

than 3 times

the LPM

value of the hydraulic pump output .

n2. There

is a partition between the oil suction pipe and the oil return pipe.

n3. Select

the oil inlet of appropriate size, and the oil inlet must be equipped

with a hole cover and a filter.

n4.

In order

to facilitate cleaning, the hydraulic oil tank is provided with side

panels of appropriate size .

n5.

An oil

drain is installed at the bottom.

n6. Install

a hydraulic filter on the suction side of the hydraulic pump, the

installation position must be more

than 500mm away from the bottom of the tank .

n7.

The air

vent must be equipped with an air filter to prevent dirt from falling

into it.

n8. Install

a thermometer and oil level gauge, so that the operator can easily

monitor the oil temperature and oil level.

n9.

If necessary,

a cooler must be installed to cool the oil temperature.

n10.

The fuel

tank must have sufficient strength to reduce vibration and deformation.

TOP

TOP

[Technical

Questions and Answers] Construction and Design of Hydraulic Oil Tanks

for Construction Machinery

[Technical

Questions and Answers] Construction and Design of Hydraulic Oil Tanks

for Construction Machinery

n( 1 )

The oil

level is too low, which affects the efficiency and working

accuracy of the hydraulic system

TOP

TOP

( 2 )

The oil

temperature is too high, the hydraulic oil is acidified early, which

affects the lubrication effect of the machine parts P 369 TOP

n Petroleum

hydraulic oilAbove 50 ℃

will accelerate oxidation,When

the oil temperature exceeds 80 ℃,

the hydraulic oil is acidified in advance ,

shortening the service life; the

viscosity of the hydraulic oil

is reduced, the lubrication effect is poor, and the machine

parts are easy to wear.n TOP