Chapter 4 Circuit Design of Air Pressure Control System

Goto Zulie teacher teaching network Pneumatic hydraulic control practice

4-1 Basic Steps of Circuit Design for Pneumatic System TOP

Step 1: Draw a working diagramP137

Step 2: Write the movement sequence of the pneumatic cylinder in the system

(1) Travel-step diagram TOP

(2) Travel-time diagram (also known as time-travel diagram) TOP

Step 3: Design

the air pressure control circuit according

to the function chart ( or

control signal chart ) TOP

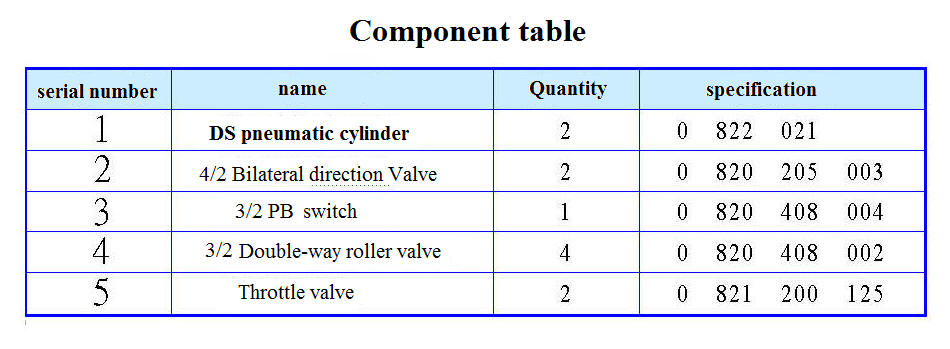

Step 4: Create Component usage table TOP

¡@

The air pressure control circuit discussed in this chapter is mainly based on the traditional pure pneumatic control. Its operating pressure is 3 to 8 kgf / cm2 , the output is between 0 to 3000 kgf, and the speed is between 0.5 to 1.5 m/sec . The following is Several commonly used pure pneumatic circuit design methods.

1 . Intuitive method.

2 . Cascade method.

3 . Cycle step method.

4-2 Intuitive method (Method or Intuition) the TOP

Signal processing method of this design

embodiment has the following ways:

1. The standing-wave

signal [ stagnation (Standing) mode ] :

It is used

for general signals. Installed at the end of the stroke of the pneumatic

cylinder with two-way rollers to generate standing wave signals, as shown in

Figure 4-8.

2. The pulse signal [ overstroke (over travel) mode ] : It is used for interference signal. Installed on the inner side of the end of the stroke of the cylinder with a unidirectional roller. After touching it, it will generate pulse signal. TOP

Intuitive design of the pneumatic circuit can use the method of Figure 4-10 to performone by one TOP

======================================================= =====================

¡@

¡@

(b) Draw a motion picture , which is represented by a displacement time diagram, as shown in Figure 4-12 . At the same time, its exercise sequence is listed in abbreviation: A + B + AB- TOP

(c) Mapping the air pressure circuit TOP

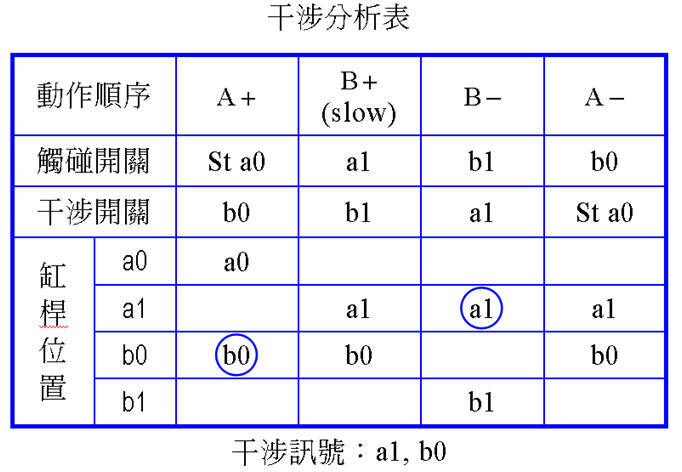

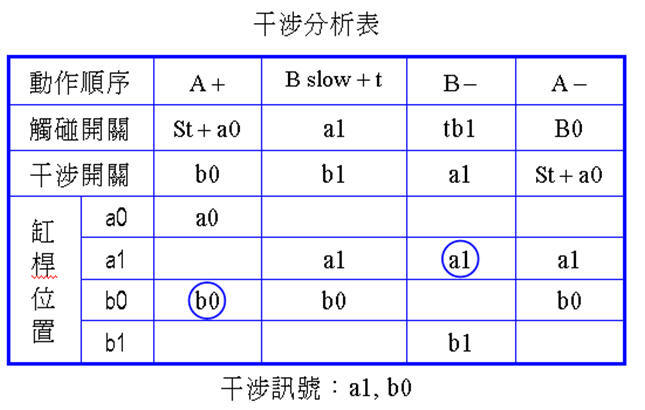

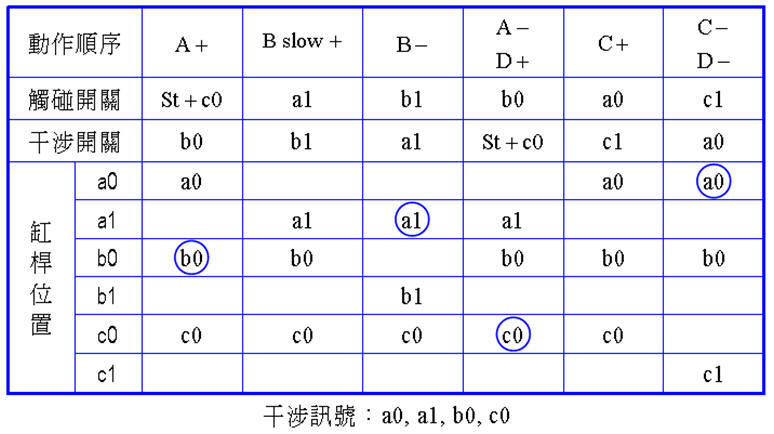

Determine the operation method used by the limit switch ( Unidirectional or bidirectional roller ) : When the signal conflict on the two sides of the direction control element is caused, the interference signal needs to be processed into a pulse signal by overtravel ( that is, the limit switch must be unidirectional Roller and move inward ) . The remaining signal elements are actuated by two-way rollers. May be established below the interference analysis table analysis of

Example 4-2 rivet riveting machine pneumatic control circuit design TOP

(a) Working diagram

(b) Displacement Time FIG TOP

(c) Pneumatic Circuit TOP

Example 4-3 Design of air pressure control loop for drilling. (a) Displacement time diagram. TOP

exercise sequence is: A + B slow +

B- A-.

¡@

(b) Pneumatic Circuit TOP

The interference signals are a1 and b0 . Change the single roller to move inward in overtravel mode.

Example 4-4 Design of a pneumatic control circuit for automatic drilling and unloading with single cycle operation and continuous processing cycle functions TOP

(a) Working diagram

¡@

(b) Displacement Time FIG TOP

(c) Pneumatic Circuit TOP

Example 4-5 Design of pressure control circuit for chemical cleaning the container. TOP

(a) Working diagram

(b) Displacement Time FIG TOP

(c) Pneumatic Circuit TOP

¡@

The method of cascade uses the signal transfer action of the 4/2 ( or 5/2) bilateral pneumatic valve ( or reversing valve ) to enable complex control to ensure that only one signal is output per action:

Take Figure 4-27 as an example:

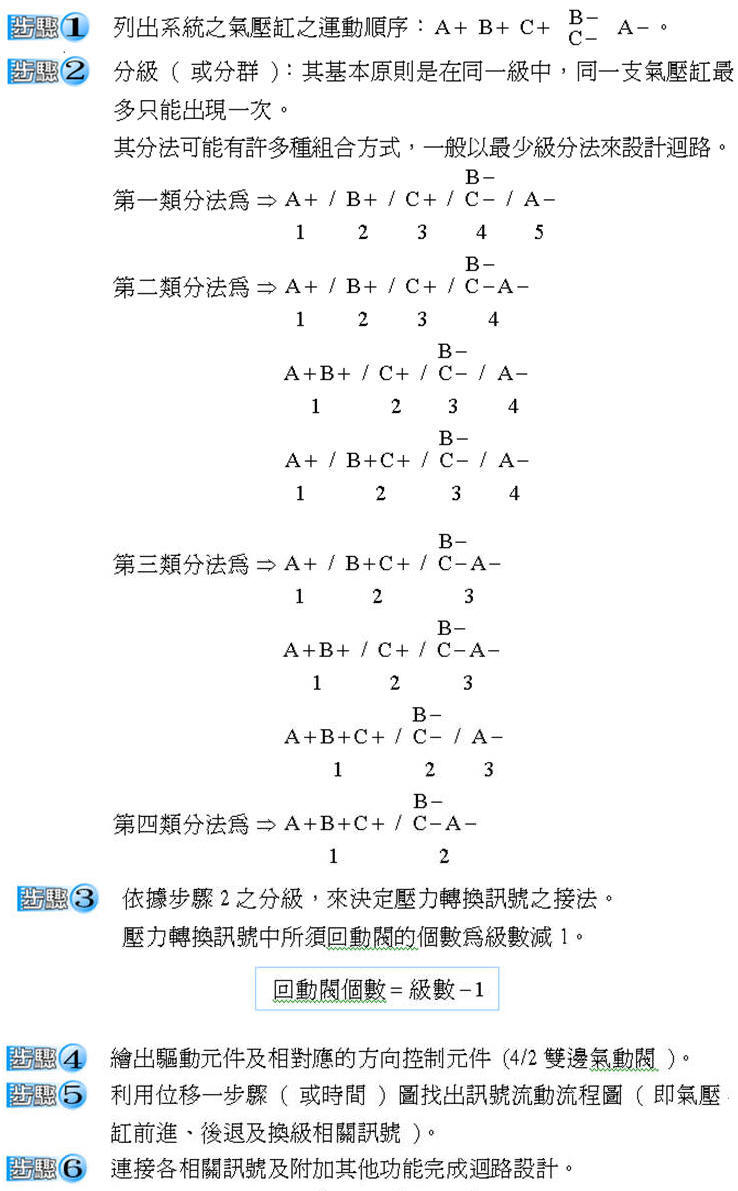

How to grade? TOP

Example 4-6 Try to design the following air pressure control circuit by cascade method. TOP

displacement time chart is shown

in Figure 4-33 .

¡@

Step 1 : List exercise sequence TOP

Step 2 : Classification.

Step 3 : Draw the pressure conversion signal.

Step 4 :

Draw the drive element, direction control element and limit switch positions and

name them alphabetically.

¡@

Step 5 : List the signal flow and connect the relevant signals to complete the loop. TOP

Example 4-7 Try to design the air pressure control circuit in the sequence of action diagram. TOP

Example 4-8 Milling working displacement time of milling machine is shown in Figure 4-40. TOP

Example 4-9 The schematic diagram of the bead blasting work and the displacement steps of the casting are shown in Figure 4-43 and 44. TOP

Step 6 : Connect the relevant signals to complete the circuit design. TOP

¡@

The displacement steps of Example 4-10 are shown in Figure 4-47. TOP

The signal flow is: TOP

4-4 Cycle Step Control Circuit Design Method TOP

Example 4-11 Printing logo continuously. Figure 4-51 is its schematic diagram. Figure 4-52 shows the displacement steps. TOP

Step 5 : Find the signal flow. TOP

Step 6 : Connect related signals and add auxiliary conditions to complete the circuit design.

Designed by maximum structure method: TOP

Example 4-12 bent and punched clamp, Figure 4-56 is the schematic diagram of this work. Figure 4-57 is the displacement time chart. TOP

¡@

Step 1 : List

exercise sequences.

Step 2 : Classification. TOP

Step 3 : Draw the pressure conversion signal.

Step 4 :

Draw the drive elements, direction control elements and corresponding limit

switch positions and name them in alphabetical form.

¡@

Step 5 : Find the signal flow. TOP

Step 6 : Connect the relevant signals, add auxiliary conditions (B , C speed control required,Manual and automatic selection) to complete the circuit design. TOP

¡@

GOTO Chapter 5 Electrical-Pneumatic Control

Goto Zulie teacher teaching network Pneumatic hydraulic control practice